- Transport & Logistics

Forklift Trucks, Material Handling, Automated Guided Vehicles, Overhead Travelling Cranes - Electromobility

Electric Vehicles, Commercial Vehicles, Electric Boats, Aerial Work Platforms, Sweeper/Scrubbers,

Ground Support Equipment - Agriculture & Construction Industries

Agricultural and Construction Machines, Builders’ Hoists, Lifting Aids - Renewable Energies

Biomass Heating Systems, Wind Turbines - Industry & Machinery/Equipment Manufacturing

Safety and Testing Technology, Textile Machines, Building Services, Medical Technology, Machine Tools,

Pumps and Compressors, Other Applications - Individual Solutions

Precision Work Series

- Industries and Applications

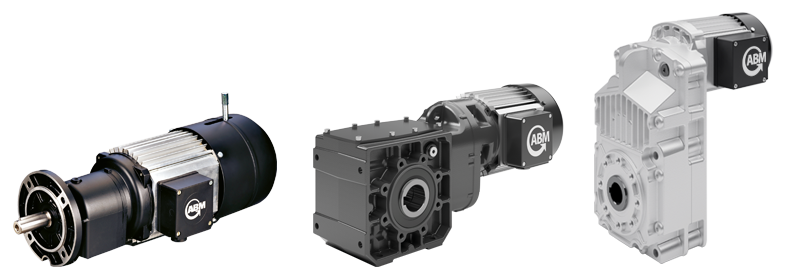

- Products

- Product Search

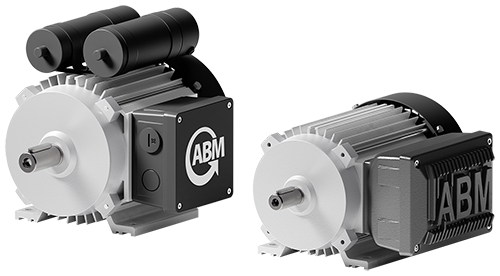

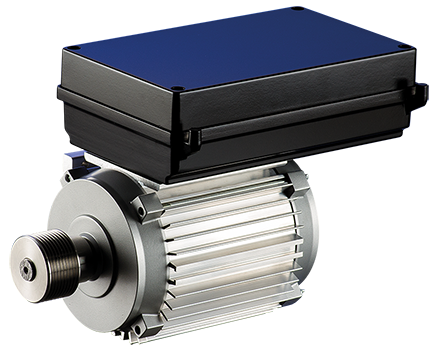

Your perfect Drive Solution - Motors

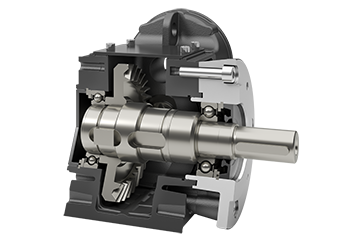

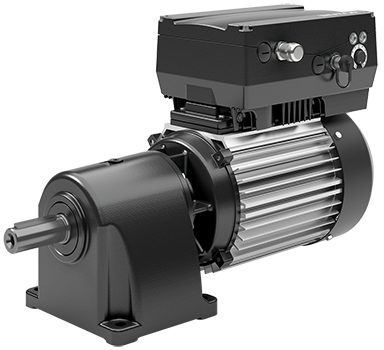

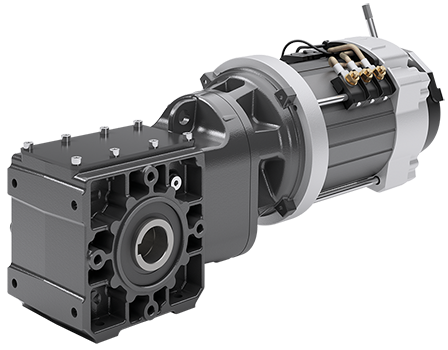

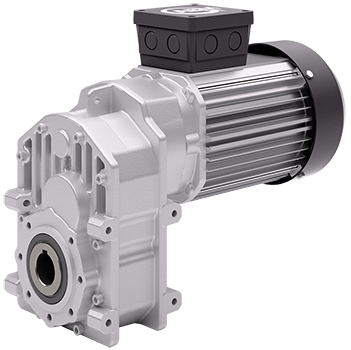

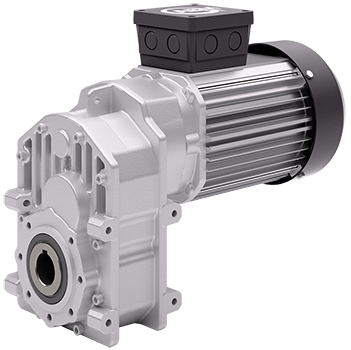

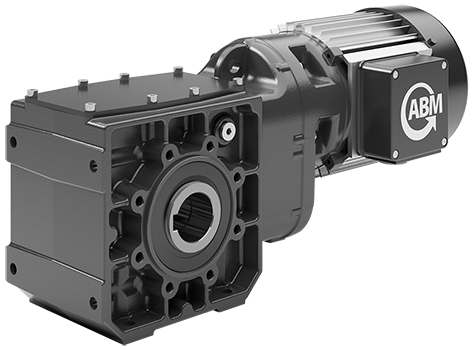

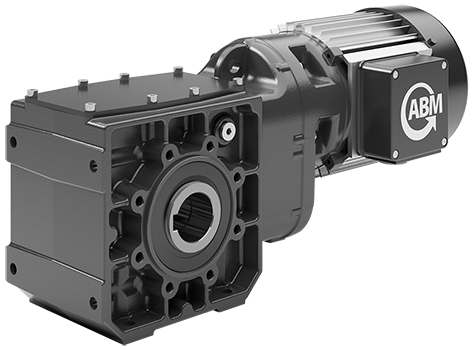

The highest Energy Efficiency - Gearboxes & Geared Motors

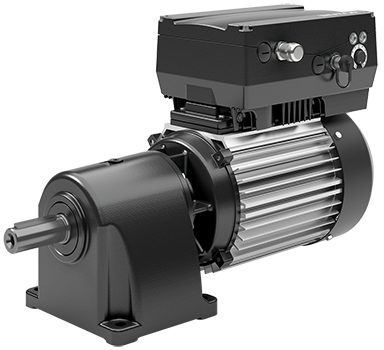

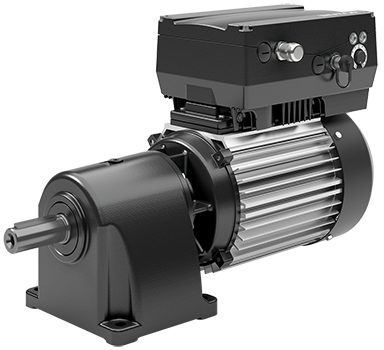

Extremely smooth Running and precise Power Transmission - Frequency Inverter

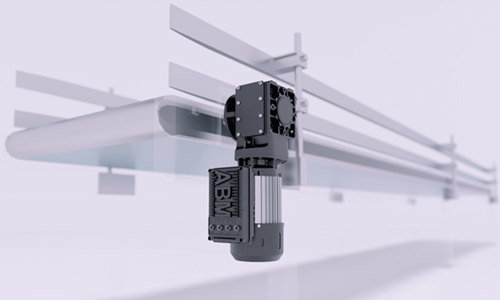

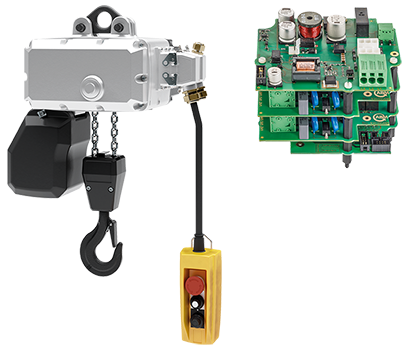

Performance when it’s needed - Drives for Hoists

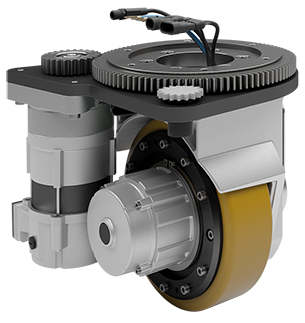

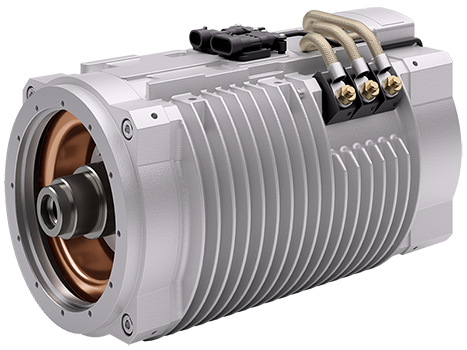

Maximum Reliability meets dynamic Running - Drives for Mobile Applications

All Drive Components from a single Source - Individual Developments

Know-how & Experience for your competitive Edge

- Product Search

- Competencies

- Engineering & Product Development

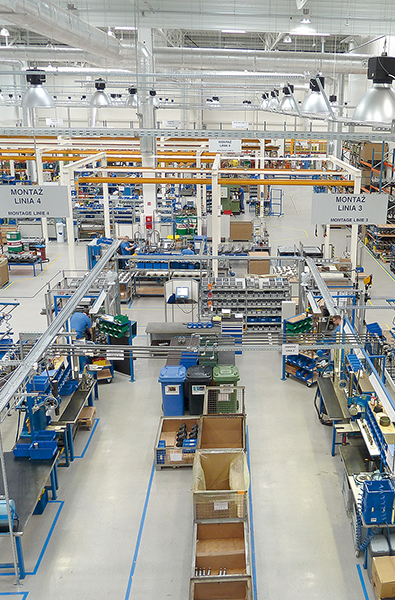

For a measurable Customer Benefit - Vertical Integration

From a single Source - Innovations & Trends

Successful Implementation of the best Ideas for forward-looking Solutions - Integrated Management System

Consistent Optimization - Supply Chain

Perfection in all Processes - Sustainable Human Resources Management

Long-term Prospects with ABM Greiffenberger

- Engineering & Product Development

- Service

- Company

- Careers

- Locations

Press Contact

Contact Us

Our press contact would be happy to assist you. Contact us for your

publication and for answers to your ABM-related questions.

ABM Greiffenberger Antriebstechnik GmbH

Dagmar Koziel | PR & Marketing

Friedenfelser Straße 24

95615 Marktredwitz | Germany

Phone: +49 9231 67-6387 Send an email

Fairs & Events

Rebuild Ukraine - International Trade Fair for Reconstruction, Energy Efficiency and Modernization of Ukraine

>Together with our sister companies from the senata Group, we will be exhibiting at the 5th International Exhibition and Conference ReBuild Ukraine: Construction & Energy.

You'll find us in Hall 4 / Booth D2 – We look forward to meeting you!

News

ABM Supports Youth Work of MSC Marktredwitz

>ABM Greiffenberger Antriebstechnik GmbH expresses its gratitude to MSC Motorsportclub Marktredwitz e.V. with a donation for their excellent support during the apprentice event “WITRON meets ABM” in November 2025.

On this occasion, around 50 apprentices from the WITRON Group in Parkstein visited ABM in Marktredwitz. Together with our ABM apprentices, they spent a day full of exciting insights – both into ABM’s production and into the new EDEKA logistics center in Marktredwitz. There, WITRON systems are used that are equipped with ABM drive solutions. The day offered intensive exchange and hands-on experiences with a strong connection to the region and to one of Germany’s most significant logistics projects.

For the activity day, the MSC provided its petrol-powered go-karts, giving the young participants an extraordinary driving experience. Another highlight was the electrically powered e-kart, which our ABM apprentices designed and built independently – a project that demonstrates technical commitment, creativity, and team spirit.

As a token of appreciation, ABM presented a donation cheque of 500 euros in support of the MSC’s youth work.

“As a company based in Marktredwitz, it is of central importance to us to support regional partners. Local, targeted assistance is close to our hearts – we want to take action where our support truly makes a difference and creates positive momentum for young people,” says Torsten Müllner, CEO of ABM Greiffenberger Antriebstechnik GmbH.

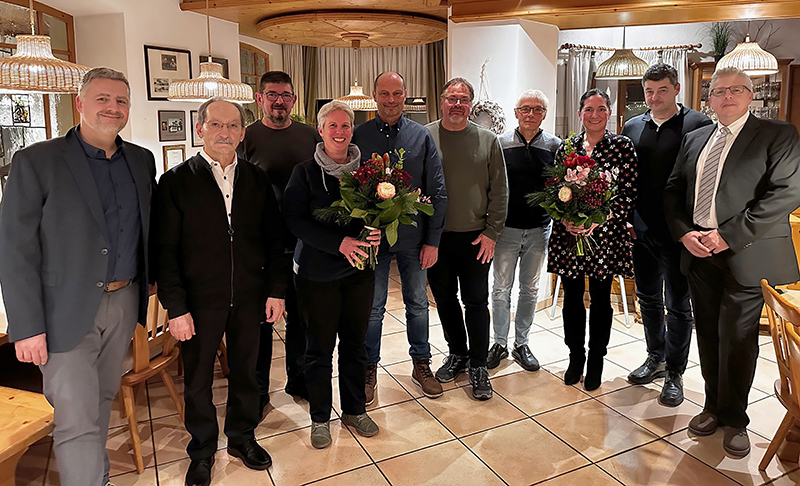

Cheque presentation to representatives of MSC Marktredwitz

From left: Roswitha Gerstner, Heinz Pogrzeba, Klaus Gottfried, Karin Gottfried, Andreas Weinberger (all MSC), Torsten Müllner (Managing Director, ABM), Christina Günther (Head of Human Resources, ABM), Eduard Eckenberger (Trainer Electrical Engineering Department, ABM)

ABM Celebrates 570 Years of Employee Service

>On Thursday evening, December 4, 2025, ABM Greiffenberger Antriebstechnik GmbH honored the decades-long commitment of its employees at the “Zum Hirschen” country inn in Rodenzenreuth. A total of 21 colleagues were recognized – together they represent an impressive 570 years with the company.

In his speech, CEO Torsten Müllner emphasized the importance of long-serving employees:

“In challenging times like these, this celebration is far more than a formal gesture. It shows how strongly ABM is supported by expertise, loyalty, passion, and experience. People who take responsibility over many years give our company a face and an identity. For this, I thank you personally and on behalf of the entire company.”

Alexander Schäffler, Head of Operations, and Works Council Chairman Jan Tröger also expressed their gratitude to the colleagues and highlighted the great value that long-standing experience brings to day-to-day operations and the company’s development.

Eighteen employees were honored for 25 years with the company, and three colleagues were recognized for an impressive 40 years of service at ABM.

The evening offered space for many personal conversations, shared memories, and reflections spanning several decades of working together. With this strong sense of continuity within the team, ABM Greiffenberger looks confidently toward future challenges – well positioned through experience, dedication, and unity.

Left to right: Jan Tröger (Works Council Chairman), Torsten Müllner (CEO), Andreas Forster, Stephanie Adler, Marco Meier, Ewald Kastner, Jürgen Ehmes, Ayhan Budan, Jürgen Simmler, Thomas Schüler, Matthias Bähr, Sabine Karawassilis, Sandro Möse, Kay-Peter Huber, Mehmet Erduran, Lars Fischer and Alexander Schäffler (Head of Operations)

Apprenticeship Day connects Two Strong Partners

>When young people experience what modern industry can achieve, enthusiasm for future-oriented professions begins to grow. That is exactly what happened on Monday, when 50 apprentices from the WITRON Group in Parkstein visited ABM Greiffenberger GmbH in Marktredwitz. Together with ABM’s own apprentices, they spent a day full of insights, exchange, and hands-on experiences – with a strong link to the region and to one of Germany’s most significant logistics projects currently underway.

Insight into Precision and Performance from Marktredwitz

To start the day, Sales Director and Managing Board Member Alexander Hecht warmly welcomed the guests and introduced the company. ABM Greiffenberger develops and produces customized drive systems – consisting of motors, gearboxes, inverters, and complementary components such as brakes. These solutions are used in a wide variety of applications, including conveyor technology, material handling, and mobile working machines.

A Fascinating Look Inside the New EDEKA Logistics Center

The next stop was the new EDEKA logistics center near Marktredwitz – a project that has attracted attention far beyond the region. The facility is one of the most modern of its kind and will secure numerous long-term jobs in northeastern Bavaria. The reason for the visit: Many of the systems operating there are WITRON solutions powered by ABM drives. On site, the apprentices were able to see how automated processes, sensors, and energy-efficient drive units work together seamlessly to ensure smooth logistics operations – high-tech with a regional signature.

An Energetic Finale with a Self-Built Electric Go-Kart

In the afternoon, another highlight awaited the group: At the “Bahneinzelgrund” site on Rößlermühlstraße in Marktredwitz, participants tested an electrically powered go-kart that ABM apprentices had built as their own project – naturally equipped with an ABM drive. The vehicle impressively combines enthusiasm for learning, craftsmanship, and technical understanding. During a small race, the fastest driver was crowned before everyone wrapped up the day in high spirits.

A Day That Shows What Is Being Created Here

“We want to inspire our young talent and show what can be achieved here on site with expertise and innovative strength,” says Alexander Hecht. “As a company from Marktredwitz, we are proud to contribute to the region’s technological development together with partners like WITRON. The visit to the EDEKA logistics center once again made it clear: When technology, automation, and strong drive solutions come together, something remarkable is created. For the apprentices, it was a day full of new experiences – for us, a day that shows: Our region has a strong future.”

With the exchange between WITRON and ABM, two leading industrial companies from the Upper Palatinate are strengthening not only their partnership but also the appeal of technical professions in the region. Young professionals are able to experience first-hand just how much innovation and expertise are rooted in northeastern Bavaria – and that modern industrial work is anything but grey and monotonous.

ABM Celebrates 405 Years of Employee Service

>On Thursday, November 28, 2024, a special event took place at the "Zum Hirschen" country inn in Rodenzenreuth: ABM Greiffenberger GmbH honored long-serving employees for their impressive loyalty and dedication to the company. Together, they celebrated an extraordinary total of 405 years of service.

In his welcoming speech, Torsten Muellner, CEO of ABM, emphasized the importance of long-serving employees for the company’s success:

"No company can be strong if it cannot rely on strong employees. With their expertise, passion, and loyalty, our anniversary employees have made a significant contribution to making ABM what it is today. We would like to sincerely thank them for this."

Jan Troeger, Chairman of the Works Council, also acknowledged the achievements of the jubilarian employees and highlighted the close relationship that has developed over the years between the staff and the company.

The awards ceremony included three employees with 25 years of service, seven employees with 40 years of service, and one particularly remarkable achievement: Mr. Anastasios Peponis celebrated an incredible 50 years at ABM—a milestone that is rarely reached.

After a festive dinner, the management and works council presented personal gifts to the jubilarians, accompanied by a review of their professional careers. The evening ended with a group photo and a relaxed gathering, during which anecdotes from many decades were shared.

ABM is proud of the commitment and loyalty of its employees—an achievement that radiates far beyond the company’s borders.

From left: Jan Troeger, Anastasios Peponis, Mario Ibanez, Beate Zehrer, Volker Michel, Mathias Friedrich, Andreas Nickl, Martina Bartmann, Michael Pollak, Torsten Muellner

Three Young Talents Begin Their Careers at ABM

>Under our motto “Together we put ideas into gear”, ABM welcomed three new trainees on September 02, 2024. With these new additions, we are currently training a total of 27 specialists.

The trainee’s journey began with a welcome day, during which their parents also participated in a factory tour to learn and have a proud feeling of where their loved ones will spend their future. Further training sessions and induction activities are scheduled for the coming weeks. “Comprehensive support and targeted encouragement during training are the key to a successful development of our young specialists,” emphasizes Torsten Muellner, CEO at ABM.

“We place great importance on fostering a strong sense of community,” explains Christina Guenther, Head of Human Resources at ABM. “In addition to varied training, our apprentices can look forward to the annual training trip in the fall - a highlight that strengthens team cohesion and encourages networking across the trainees.”

Get to know us

Would you like to find out more about your opportunities at ABM and the benefits we offer? Then visit us at one of the following training fairs and get all the information you need first-hand:

- September 28, 2024 – Fichtelgebirgsrealschule Marktredwitz

- October 19, 2024 – School Center Kemnath

We also offer orientation days and student internships to help you explore your career options. Visit our careers portal at www.abm-drives.com for all the details.

Applications for the 2025 Training Year

We are now accepting applications for 2025. The process is simple: choose your desired apprenticeship at https://www.abm-antriebe.de/en/careers/job-offers, enter your details, upload your certificates and CV—and you're in!

From left to right:

Marc Mayer (Youth & Trainee Representative), Marco Meier (Vice Chairman of the Works Council), Eduard Eckenberger (Trainer Electrical Engineering), Jan Tröger (Chairman of the Works Council), Simon Pöllath, Emilian Gschwend, Christina Günther (Head of Human Resources), Torsten Müllner (CEO) und Sebastian Prechtl (Training Manager)

Not in the picture: Our new apprentice Younes Achernan

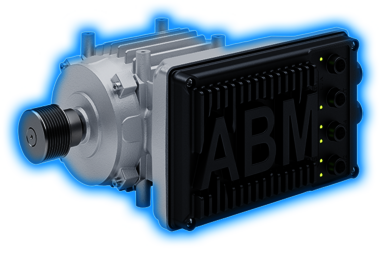

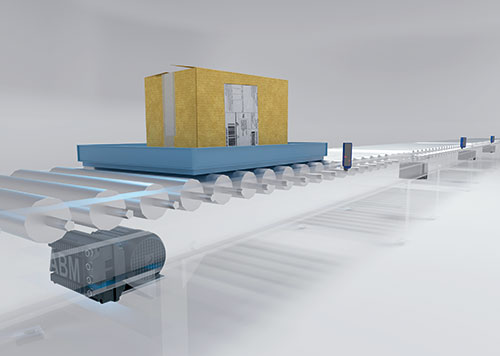

Efficient and Economical Horizontal Movements

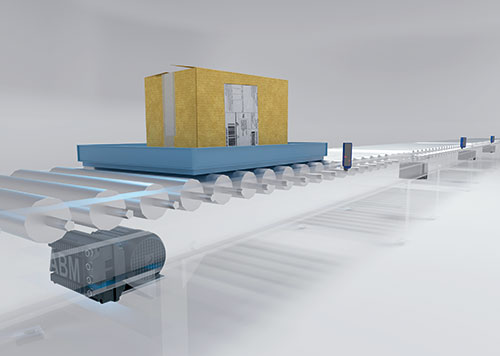

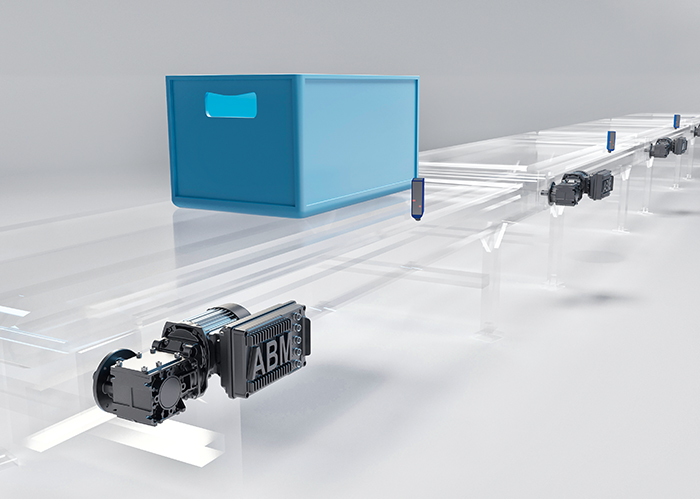

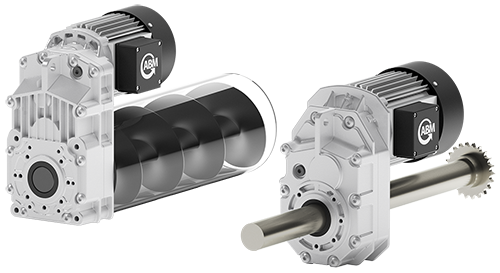

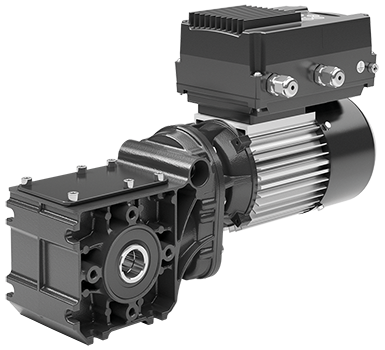

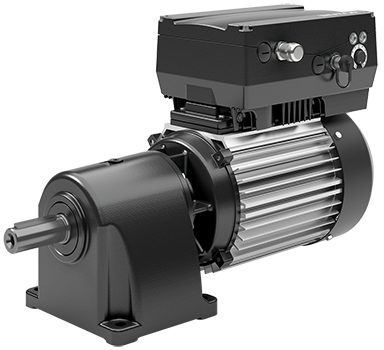

>One of ABM Greiffenberger's product innovations is the highly integrated drive system for roller conveyors. During development, the specialists focused on making it compact, efficient and economical. This provides users with a particularly powerful and productive solution for horizontal conveyor technology.

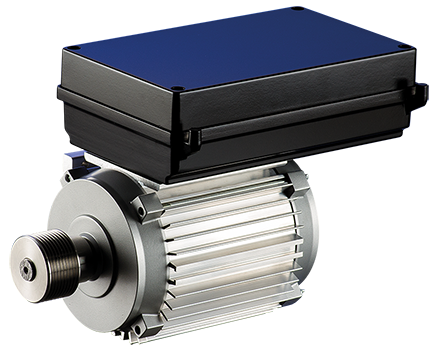

The drive system for roller conveyors consists of a synchronous motor with an integrated controller. It has a rated output torque of 4.5 Nm with almost double the overload capacity and can move loads of up to 180 kilograms. The direct drive is a complete one-piece motor-inverter unit. This universally applicable new development is suitable for a wide range of container conveyor technology applications, including roller conveyors and curved belts.

One for All

ABM covers all common requirements in container and pallet conveyor technology with one motor. This allows system integrators to reduce complexity and the number of variants, which has a positive effect on overall costs. The drive can be easily integrated into specific application thanks to the various mounting options. Due to the high temperature range of -30 to +40 degrees Celsius, it is also predestined for deep-freeze storage.

ABM has optimized the motor technology and thus increased the energy efficiency to a maximum – this reduces the CO2 footprint. The overall system is also sustainable and resource-saving thanks to an optimized use of materials. Another advantage for the operator is the rapid return on investment: the reliable and efficient performance of the sensorless controlled drive also saves significant costs. As a result, this system solution works without the encoders, which are cost-intensive and prone to fail.

The drive specialist has designed all of the controller's connections to be pluggable. This significantly reduces the installation effort. The controller is easily controlled via the integrated multi-protocol Ethernet interface. System updates are also readily available via this interface. There is also a predictive service module: Machine-to-machine communication enables predictive maintenance and therefore smooth operation of the system - the user benefits from very high availability.

Also for high loads

As an intralogistics partner, ABM also offers complete system solutions for extended bin or pallet conveyor technology, i.e. for transporting loads of up to one ton per load carrier: Intelligent combinations of motor, gearbox and controllers from the modular system reduce the number of variants here too. The motors can be combined with angular, helical and parallel shaft gearboxes. This allows users to minimize their stock and still have the right component on hand quickly when required, another substantial benefit.

The new highly integrated drive system for roller conveyors impresses with maximum efficiency and economy.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

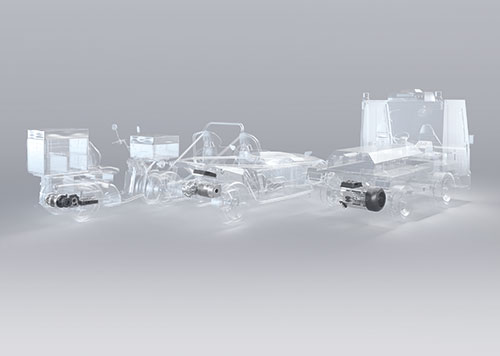

Measurable Customer Benefits for a Competitive Advantage

>In every industry - often even within a product range - very specific requirements apply to the drive solutions used. Only when these are fully integrated, it is possible to achieve the optimum level of performance and efficiency. With its comprehensive know-how, ABM develops and manufactures electric motors, gearboxes and controllers. With its broad product range and high level of manufacturing integration, the full-range supplier finds the optimum solution for every requirement.

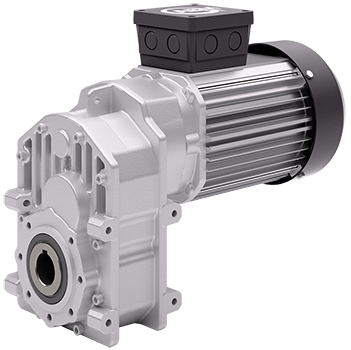

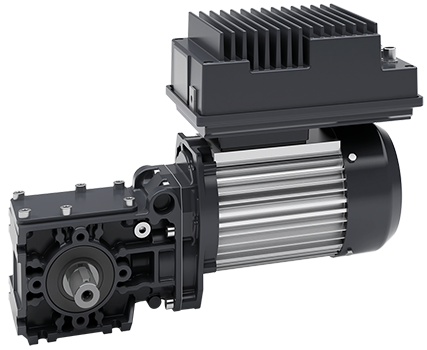

ABM defines performance not only just by torque, but above all by the measurable usefulness to customers. With its engineering expertise and state-of-the-art testing technologies, the drive specialist develops a broad technology platform for motors, gearboxes and controllers. Using an intelligent modular system, the supplier can adapt the various gearbox designs to the respective application and provide the user with a quickly available and cost-efficient drive solution in terms of functionality and efficiency. ABM also offers concepts adapted to specific industries. ABM is also a development partner for individual system solutions that are precisely tailored to a specific application.

These include, for example, generators that are installed in a truck axle module. This module generates energy while the trailer is in motion in order to supply cooling units with CO2-neutral and quiet electricity. The two built-in generators provide double the power and reliability. ABM has designed the housing specifically for the application to ensure optimum air cooling. This solution is designed in protection class IP6K9K. This means that the housing is dust-tight and can be cleaned under high pressure. The generators are optimized and compactly housed in the axis. Durable, robust and efficient, they form a reliable basis for sustainable and powerful energy generation.

ABM has developed another solution for medical and rehabilitation technology. Special drives are often used in these areas, which have to combine many functionalities in a very small space with very high demands on safety, precision, comfort and reliability - for example in stair lifts. In addition to the travel movement along the stairs, seat leveling is also required to compensate for different gradients. The two functions of travel and leveling are conveniently located in one drive unit. And because the housing can absorb external forces, this solution requires fewer components. The drives also run particularly quietly and smoothly. The drive specialist supplied a compact unit comprising motor, gearbox and controller from a single source.

For highly efficient pump systems, the ABM engineers designed a pump and gearbox housing from just one part. The drive solution is precisely adapted to the required function, interfaces are eliminated and the installation space is used to the maximum. ABM thus demonstrates a very high level of system integration. The pump can be operated using a special eccentric mechanism. The combined gear and pump lubrication ensures sustainability. This unit is also easy to service and maintain.

ABM has also tailored compact and safe drives for construction elevators precisely to their function. The interface is designed specifically for the application. Because load-bearing and guiding elements are integrated into the gearbox housing, the drive not only moves the construction elevator, but also ensures that the cage is held securely and runs reliably with guidance. The drive can be installed quickly and easily thanks to plug-and-play. And because ABM was able to reduce the number of components, the user saves costs.

Customized system solution for the electrification of a truck refrigeration unit: maximum emission reduction and efficient use of kinetic energy when driving and braking.

Precise, convenient and reliable: Drive units for stairlifts.

Compact and safe drives for construction elevators: The gearbox housing incorporates load-bearing and guiding elements.

Focus on Sustainability and Efficiency

>ABM will present complete drive solutions for a wide range of intralogistics applications at the upcoming LogiMAT in Stuttgart (19–21 March) in Hall 3 at Booth 3B15. The system supplier tailors the drive solutions in close cooperation with the customer to his unique application and requirements – while maintaining a strong focus on ensuring sustainability and efficiency of the proposed drive package.

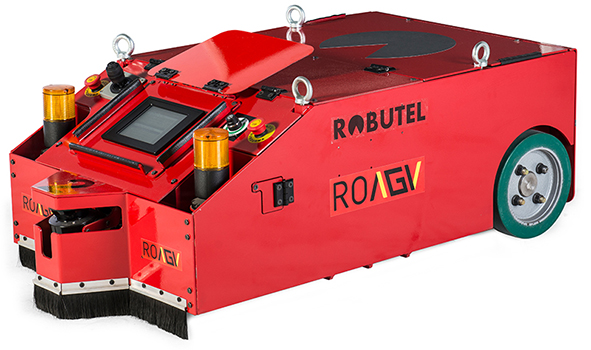

As a full-service provider, ABM develops and manufactures drive systems for stationary and mobile applications in all areas of intralogistics. In electric buses or trucks they are used, for example, for auxiliary units such as hydraulic pumps, air compressors and cooling fans. They are also installed in pallet trucks, forklift trucks and automated guided vehicles (AGVs) as well as in container and pallet conveyors, cranes and industrial doors. The system solutions consist of motors, gearboxes, brakes and inverters – selectively for mains or battery power supply.

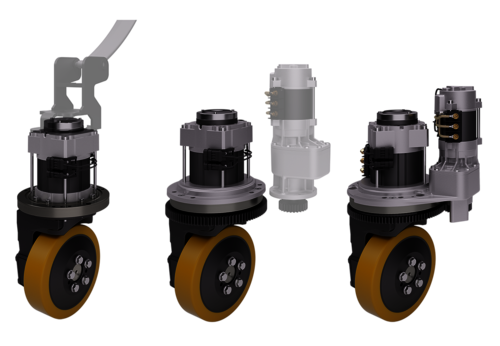

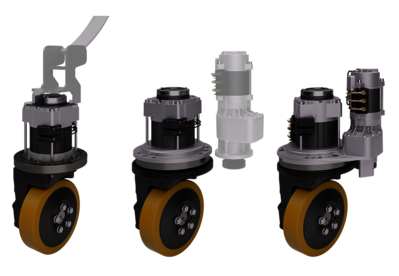

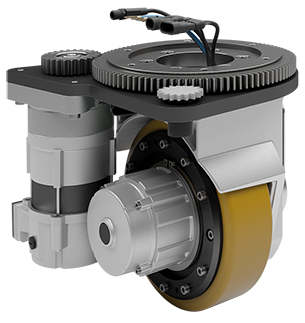

All Drive Components for Traction, Lifting and Steering

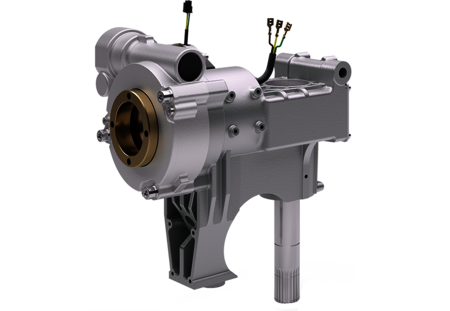

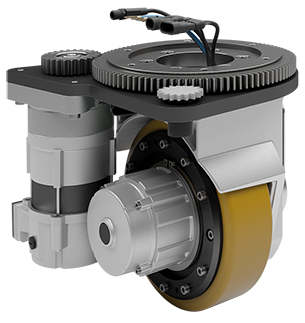

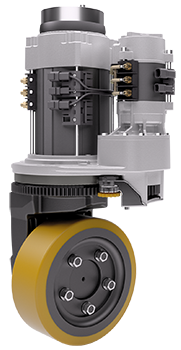

ABM offers all drive solutions for driving, lifting and steering of forklift trucks as a single source. The motors, gearboxes and inverters comply with strict environmental requirements, are safe and are extremely responsive for precise movements even at low speeds. One of the available drive options are the two stage bevel gearbox units of the series TDB. These drive units come with plug-and-play capability for easy integration and are both powerful and energy-efficient. They offer high power densities at optimum efficiencies. The compact series is available with manual or individual steering as well as with integrated electric steering drive.

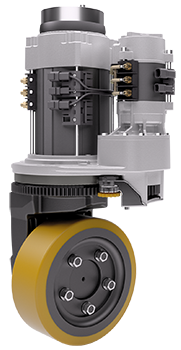

The drive specialist will present the TDH series electric-steering hub-wheel drive units with inverters for AGVs, pallet jacks, cleaning machines, industrial trucks or track-bound vehicles. These units are compact, robust and capable of handling high static and dynamic wheel loads. For the motor control specific sensors that record speed, rotor position and temperature are included.

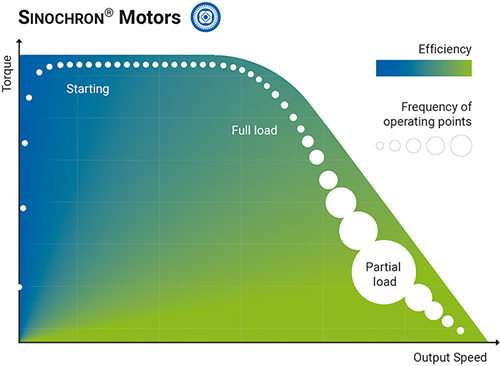

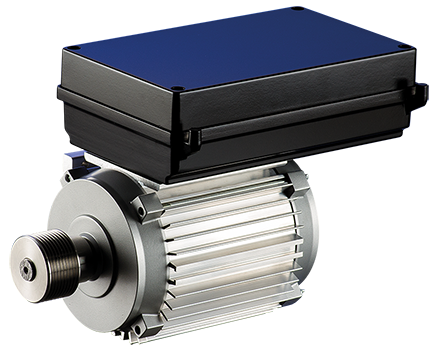

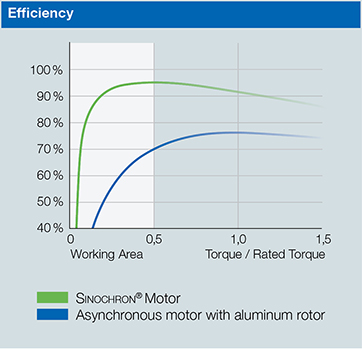

Driven with High Energy Efficiency

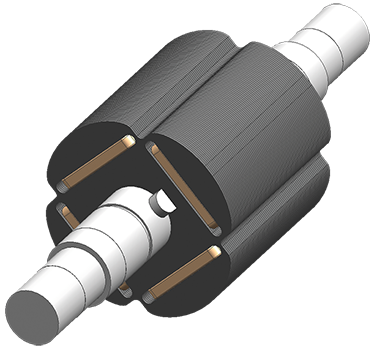

The wide product range includes induction motors as well as the sustainable and high-efficiency Sinochron motors. Because Sinochron motors already meet the requirements of premium energy efficiency class IE5, users do not have to worry about compliance with legal regulations. The synchronous motor has a compact design and can easily be integrated into systems. With the unique feature sensorless control, the inverter calculates the rotor speed and the instantaneous rotor angle from electrical feedback. With this data, the currents for torque generation can be fed precisely to the motor. The motor can be optimally controlled over a wide speed range with a high starting torque – without the need for expensive sensors.

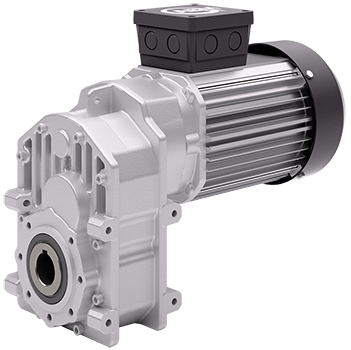

The comprehensive product range also contains helical gearboxes with torques from 30 to 2000 Nm, parallel shaft gearboxes with 50 to 2300 Nm and angular gearboxes with 60 to 450 Nm. They can be supplied with flanges, solid shafts or hollow shafts. Also available are brakes and sensors.

Via an intelligent modular system, the provider can adapt the various gearbox configurations to the respective application and rapidly deliver a drive solution with high cost efficiency with regard to functionality and efficiency. ABM also offers industry-tailored concepts. For special applications, ABM can also develop completely new system solutions as partners in close cooperation with customers.

Highly Integrated Drive System for Accumulation Roller Conveyors as a Trade Fair Premiere

One innovation example is the highly integrated drive system for accumulation roller conveyors. During development focus was placed on compactness, maximum efficiency and cost. Efficient and dynamic motors are installed as direct drives for small loads. For higher loads – such as in pallet conveyors – the drives can be combined with angular, helical or parallel shaft gearboxes. Added to that is an inverter series designed especially for intralogistics applications. This series is available in three sizes with power outputs of up to 2.2 kW and a high overload capacity of 250 per cent. With the series, ABM covers all common applications in container and pallet conveyor systems. And because most drives in intralogistics only operate at part load, the Sinochron motor with sensorless control are the perfect match.

Sustainability Award

With the ePower axle module from BPW Bergische Axis KG, ABM will present an example of sustainability and efficiency in Stuttgart. The axle module generates energy when the trailer is in motion and uses it to power cooling units quietly and in a CO2-neutral manner. Two generators from ABM double the power and make the system fail-safe. The overall system, awarded the European Transport Award for Sustainability in the category ‘Components and Aggregates’, not only addresses the challenges of the industry, but actively contributes to the avoidance of impending driving bans and delivery restrictions.

ABM supplements ePower with many customer benefits. The generators are optimized and housed compact in the axle. Through their longevity, robustness and efficiency they provide a reliable basis for sustainable and high-performance energy generation throughout the entire trailer journey.

New Development: Externally Excited Motor

An externally excited motor for e-mobility, which is still under development at ABM, is also sustainable and efficient. At its booth, ABM will offer an early look at the innovation, which is completely free of rare earth magnets. The good field weakening behaviour mirrors the torque/speed requirements for traction drives, because they can be controlled more efficient and variable.

ABM supplies drive solutions for intralogistics as a single source. The customer receives a tailored, installation-optimized, highly energy-efficient solution for the given application. With this, ABM continues to pursue its goal of delivering high-quality, reliable drive solutions and as a partner supporting its customers with engineering and manufacturing expertise.

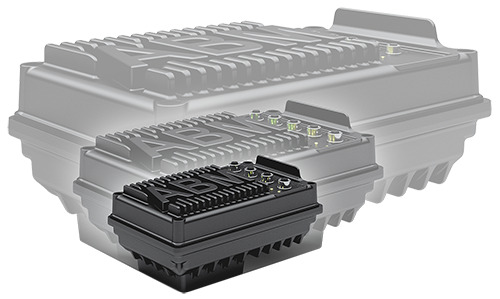

ABM’s new inverters are used in all common container and pallet conveyor applications.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

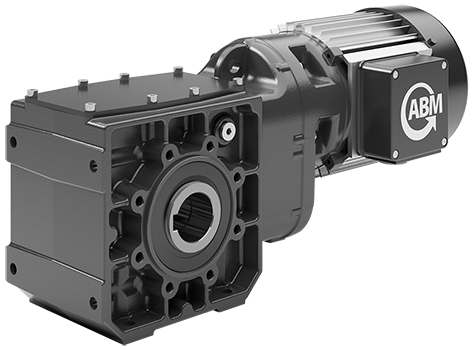

The two-stage bevel gearbox drive units in the TDB series have plug-and-play capabilities for easy integration.

As a systems supplier, ABM offers all drive systems for driving, lifting and steering forklift trucks and pallet trucks from a single source.

ABM presents highly flexible System Solutions at SPS 2023

>ABM Greiffenberger will present all-in-one drive solutions at the SPS (14 through 16 November in Nuremberg, Germany) in Hall 3a at Booth 400. With solutions precisely tailored to individual requirements, high quality is ensured. Depending on the task, the systems supplier can assemble one using standard modules, supply a solution for a specific industry or develop a tailored solution in close cooperation with the customer as partner.

As a full-service provider, ABM Greiffenberger develops and manufactures drive systems for stationary and mobile applications. These are suitable for numerous industries such as machinery / equipment manufacturing, intralogistics, electric vehicles, medical technology, energy, gases and fluids, and many other fields. The drive systems include not only induction motors – but also permanent magnet synchronous motors: With their high efficiencies, motors in this series can further improve the energy balance of the drive systems. The requirements of premium energy efficiency class IE5 are already met. The Sinochron motor features a compact design, can easily be integrated into an overall system – and offers sensorless operation. As a result, the series can apply the full torque immediately for starting from a standstill. This is a clear added value that sets it apart from other products on the market, especially in terms of availability, performance and cost.

The portfolio also includes helical, parallel shaft and angular gearboxes with various configurations, e.g. with flange, solid shaft or hollow shaft. ABM additionally offers gearboxes, combined with induction or Sinochron motors, with inverters for specific industries and applications. Inverters are optionally available with various BUS systems for enabling connectivity – ‘digitalization’ is the keyword here. The inverters can be installed centrally in the control cabinet or in decentralized positions in the field and are also available in customized versions.

The drive specialist thus has myriad combination possibilities available for a wide range of applications – to provide both perfectly fitting standard or custom solutions. To be able to do this, ABM has an intelligent modular system containing the various gearbox configurations, which the provider adapts to the respective application. The user receives a drive solution that is quickly available and offers cost efficiency in terms of functionality and power consumption for the given application.

ABM also offers industry-specific drive solutions – such as hoist drives: Parallel shaft geared drive units with additional special properties for hoisting applications such as bridge cranes.

If a special application-specific drive system is needed, ABM can also develop a completely new system solution in close cooperation with the customer as a partner. The individual solution is precisely tailored to the requirements and offers maximum added value in terms of performance and energy efficiency as well as permanently and considerably lowered costs.

ABM offers system solutions from an extensive portfolio of motors, gearboxes and controllers.

Individually tailored to conveyor applications: Geared motor and inverter are selected from a modular system.

ABM also supplies industry-specific lifting solutions consisting of geared motors and inverters.

System integration at the highest level - Specific solutions are developed for a given application, e.g. a stair lift, in close cooperation with the customer.

ABM Greiffenberger welcomes nine Trainees

>This year the ABM Greiffenberger team welcomes nine trainees. Starting on September 01, 2023, they are learning technical professions like electronic technician for machines and drive technology, mechatronic engineer, tool maker and metal cutting machine operator. With them, a total of 31 young talents complete their apprenticeship at ABM Greiffenberger. All graduates from 2022/2023 were offered permanent employment.

„We focus on targeted development of young people to meet our need of skilled trades. Our trainees receive comprehensive support and encouragement. After successful completion, we offer a wide range of prospects and career paths“, explains Thomas Heim, Managing Director of ABM Greiffenberger Antriebstechnik GmbH. As an employer, ABM Greiffenberger offers many advantages. “During the apprenticeship, we cover the costs for work clothes and textbooks, for example, and good results in the intermediate and final exams are rewarded. In addition, our trainees – like all employees can cash in on numerous benefits such as job bikes, employee discounts, a company pension scheme, holiday and Christmas bonuses and much, much more.”

Vacant Apprenticeship Positions 2023 / 2024

In order to successfully meet the challenges of filling apprenticeship positions, ABM Greiffenberger offers young people assistance in choosing a career at an early stage. Be it through meet and greet days and student internships at ABM, participation in recruiting fairs as well as presentations at schools or even an own day of training.

On the career portal www.abm-drives.com of ABM Greiffenberger, interested parties can always find all open apprenticeship positions for the year 2024 as well as information on further entry and career opportunities. You are also welcome to meet our team in person. We will be available at the following events to answer all your questions about training:

- Apprenticeship Fair in Marktredwitz (September 30, 2023)

- Apprenticeship Fair in Kemnath (October 14, 2023)

- Apprenticeship Day at ABM Greiffenberger (October 28, 2023)

From left to right:

Marc Mayer (Youth & Trainee Representative), Jan Tröger (Chairman of the Works Council), Matthias Lippert (Trainer Mechanics), Mirko Schönfelder, Bastian Scherzer, Tim Benker, Ewgenij Rykunov, Dominik Marx, Julian Linß, Fabian Hösl, Vanessa Prechtl, Julia Wunderlich, Eduard Eckenberger (Trainer Electrical Engineering), Dr. Norbert Neumann (CEO) and Bernhard Wenning (Training Manager)

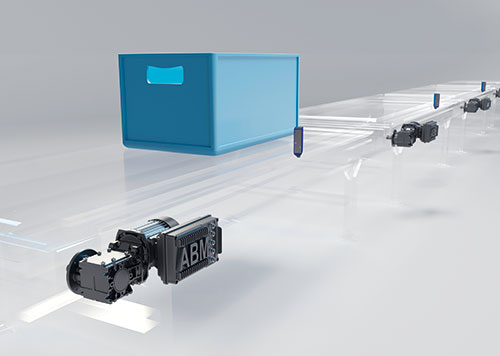

All from a single source

>ABM Greiffenberger supplies complete drive solutions for intralogistics. If necessary, the systems supplier can adapt the solutions, consisting of motors, gearboxes, brakes and frequency inverters, for specific applications and customers. ABM works closely and in partnership with the customer. The solutions are used in applications including automated logistics systems with conveyors, lifting equipment and forklift trucks as well as automated guided vehicles (AGVs). The customer receives everything from a single source.

‘As a full-range provider of drive technology, we develop and manufacture tailored drive solutions for intralogistics that can be optimally integrated into the respective applications,’ explains Stephan Thoma, product manager for inverters at ABM Greiffenberger. One such solution is the highly efficient Sinochron motor. The permanently excited synchronous motor can be used, for example, without a gearbox as a direct drive in container conveyors for small loads of up to 180 kg. The motors have especially high efficiencies in the part-load operational range in which the drives in the systems are primarily operated. Typical travel speeds are 0.3 to 1.5 m/s.

‘Thanks to its special design, the series is perfect for operation with sensorless control. In addition, even the smallest IEC frame size of 63 can already reach nominal torques of 4.5 Nm. This drive solution differs from the induction motor by a short-time overload capacity that is approximately twice as high,’ reports Thoma. Because of this power density, ABM can make the motor series more compact. This is a clear advantage for the design engineer, who usually receives a smaller drive and can thus reduce the installation space and energy consumption. Via the sensorless speed control, the control system calculates the rotor speed as well as the rotor angle at a given time from the electrical feedback. With this information, the currents for torque generation can be fed precisely to the motor. As a result, even without an expensive encoder, the Sinochron motor has outstanding control characteristics over a large speed control range. Because the drive does not require any sensors, it is also more robust. This ensures maximum system availability – a clear advantage for the total cost of ownership. Depending on the application, the service life of the drives can reach 50,000 hours.

‘Our Sinochron motors are energy-efficient and can be operated over a wide temperature range,’ reports Thoma: ‘Our customers can use the series at temperatures of -30 °C to +60 °C and thus even in deep-freeze storage facilities.’

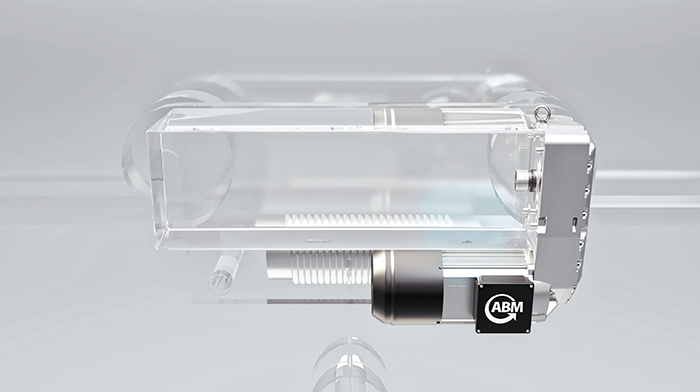

Even for Heavy Loads with added Gearbox

For extended container or pallet conveyor systems, i.e. for transporting loads of up to a tonne per load carrier, ABM combines its motors with helical, parallel shaft or angular gearboxes. Specifically for these applications, ABM has supplemented its parallel shaft gearbox series with the two compact two-stage types FG182 and FG282, offering nominal torques of 180 Nm and 280 Nm respectively. Users benefit from high permissible radial loads and universal mounting options for the parallel shaft gearboxes. Hollow and solid shafts as well as shrink discs are available. The series can be supplied with or without flange. Because the gearboxes are also light and compact, they are easy to handle during installation.

ABM Greiffenberger always focuses on customer needs. ‘We select the best drive solution in terms of functionality and efficiency from our modular system for the given application,’ says Thoma. The modular principle means that even special requirements of the system manufacturer can be met with standard components. This positively affects the quality because only proven modules are used. Various mechanical and electrical interfaces are available to simplify installation. ABM realises all connections as plug-and-play solutions. Plug-in connector systems ensure fast, error-free installation.

ABM also develops completely new system solutions. The big advantages of an individual solution are the maximum added value and the permanently and considerably lowered costs that result because these drives are precisely tailored to the requirements.

Without a Frequency Inverter, nothing works

Most applications in intralogistics are implemented with speed control. ABM Greiffenberger offers an extensive portfolio of products for this, which is rounded off with two new sizes made especially for container and pallet conveyor systems. ‘With power outputs of up to 2.2 kW, we cover all the applications needed in conveyor technology,’ reports Thoma. ‘The user profits from optimal control characteristics for both induction and Sinochron motors.’ Because the frequency inverter controls the permanently excited synchronous motor without any sensors, costs are lowered and availability is increased. The devices are designed for a service life of 30,000 hours under full load in continuous operation. The pluggable connection allows for an easy and quick installation. Users receive the new frequency inverters with a protection rating of up to IP54 and an overload capacity of 250 per cent. The frequency inverters are also suitable for use at temperatures of -30 °C to +40 °C and thus even in deep-freeze storage facilities.

Frequency Inverters with numerous Features

Plug-in connections for the power supply (daisy chain principle) and control terminals/inputs make installation fast and easy. Using the Ethernet-enabled BUS systems the inverters communicate with higher level controls.

The inverters can optionally be equipped with brake choppers and the ability to control mechanical brakes. Thoma explains: ‘With sensorless control we ensure a maximum speed control range. This feature sets us apart from our competitors.’ The result is lowered costs and higher availability. The decentralised inverters can be integrated on the drive and are also suitable for field use in the vicinity of the motors as wall-mount versions. The inverters use machine-to-machine communication to connect to higher-level controls, making predictive maintenance possible. The inverters are thermally independent and require no additional fans. ‘Through the intelligent combination of motor, gearbox and inverter from our modular system, we can control the complexity,’ says Thomas. The reduced number of drive variants represents a huge advantage for users when it comes to storage, service etc.

As a systems supplier, ABM can offer drive solutions for most applications in warehouse logistics – from small roller conveyors to pallet conveyors. ‘The user receives everything from a single source,’ says Thoma.

ABM’s new inverters with power outputs of up to 2.2 kW are used in all common container and pallet conveyor applications.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

Container conveyor technology: a belt conveyor with an angular gearbox including an ABM inverter as a drive.

Chain conveyor for pallet transport: ABM’s parallel shaft geared drive unit combined with the ABM inverter is ideal for heavy loads.

Compact Platform with the Highest Level of Integration

>Electric drives in conveyor systems, lifting equipment and forklifts are the motors that drive modern, efficient and reliable intralogistics. ABM Greiffenberger develops and manufactures platform-based systems for stationary and mobile applications. The drive solutions consisting of motors, gearboxes, brakes and frequency inverters tailored to specific applications are developed by the specialists at ABM Greiffenberger in close partnership with their customers.

‘Traction, lifting and steering in forklift trucks, for example, require both know-how and the right drive components,’ says Mayk Krüger, Senior Manager of Material Handling at ABM Greiffenberger. ‘Our solutions consistently comply with strict environmental requirements, are particularly safe and enable precise movements even at low speeds thanks to their high responsiveness.’

ABM supplies all drive components, including motors, gearboxes, sensors and inverters, from a single source. And that’s not all: The drive specialist develops and manufactures complete gearbox–motor drive units in-house – this system expertise sets the company apart from the competition. With the modular system, ABM is always able to supply the right solution – irrespective of the vehicle type.

‘Our drives make dynamic movement and precise manoeuvring of industrial trucks possible for users, even in tight spots,’ Krüger says. ‘Also, our solution provides forklift trucks with excellent climbing performance.’ The TDB series can easily be integrated into a given application via plug and play. The two-stage bevel-helical gearbox drive unit offers high performance and low energy consumption. It can be used for both manual and electric industrial trucks. It is characterised by high-power density and outstanding efficiency. Combined with a steering drive and equipped with a fully integrated and reliable sensor monitoring system, it gives the user a fully integrated traction and steering drive solution. ‘Through the vertical design, the small envelope size and the numerous series options, this gearbox drive unit is ideal for a multitude of applications – for example, in reach trucks, tow tractors, automated transport systems and sweeper/scrubbers,’ says Krüger, describing the extensive applications for the drives. Users can work reliably for lengthy periods, even with smaller batteries.

Various steering options

ABM Greiffenberger offers the bevel gearbox drive units for wheel diameters of 230 and 254 mm based on power output, speed and load capacity: Gearbox ratios and motor performances can be tailored precisely to given applications. The compact TDB series offers drive torques of up to 750 Nm. ‘It can be equipped with various steering options,’ says Krüger. The manual steering system, for example, is suitable for direct mounting on the drawbar. The user receives a space-saving, robust and accordingly long-lasting solution. An electric power steering system can be realised with external steering via spur gear. If necessary, ABM can supply a zero position sensor for the steering position as well as an absolute encoder for steering right on the traction gearbox. A third possibility is an integrated electric steering drive. The user profits from redundant steering monitoring, maximum ride comfort and a high level of safety.

For the traction area, ABM offers temperature monitoring via temperature sensor. Speed recording is done via an incremental encoder with up to 64 pulses per revolution. All AC traction motors offer energy recuperation via regenerative braking to save energy. An electromechanical holding brake is integrated for parking and emergency stopping. Krüger says: ‘With this diversity of functionalities and possible combinations, we support both developers of individual applications and OEM project managers of cross-fleet platforms with suitable drives.’

Systems Supplier with high Level of Development Expertise

ABM Greiffenberger scores points both with its extensive know-how and experience in the development of application- and customer-specific drives and with its platform concept, which ensures that customers quickly receive cost-optimised solutions. ‘However, we can also specifically address customer requirements,’ says Krüger. ‘Thus, we are not a standard supplier and offer our customers a measurable added value.’

ABM supplies all products, including motors and gearboxes as well as suitable electronics, from a single source.

As a system supplier, ABM Greiffenberger offers all drive components for forklift truck traction, lifting and steering from a single source.

Manual or electric steering versions are available. A fully integrated drive unit can be supplied and consists of electric steering and redundant steer motion monitoring directly on the drive wheel.

Bevel Gear Drives TDB 230 with integrated electric steering: Highest integration and impressive driving comfort and safety.

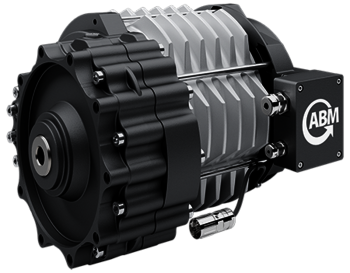

Motors for High Load Peaks and Continuous Performance

>Electric drives in conveyor systems, lifting equipment and forklifts are the motors that drive modern, efficient and reliable intralogistics. ABM Greiffenberger develops and manufactures platform-based systems for stationary and mobile applications. The adaptable drive solutions consist of motors, gearboxes, brakes and controllers and are developed by the specialist in close partnership with customers.

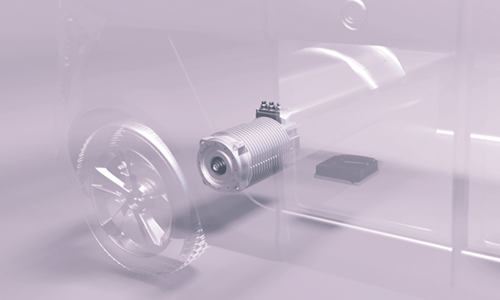

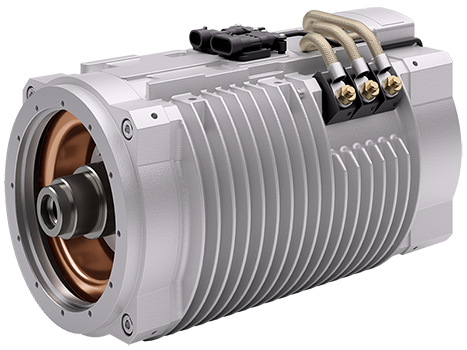

Drives for electric vehicles must meet high expectations: They have to be environmentally friendly, efficient, powerful and inexpensive to maintain. “ABM Greiffenberger already started to transfer its know-how from battery-powered drives to E-mobility before the turn of the millennium and even back then was already able to implement the first projects,’ reports Mayk Krüger, Senior Manager of Material Handling. Users benefit from the full-service provider’s decades of expertise: They receive powerful drives with high efficiencies.

Compared with standard motors, the ABM drives are much more compact – and also extremely robust, durable and maintenance-free in harsh operating conditions. ABM offers a platform concept with manifold options – customers receive cost-optimised, easy-to-integrate system solutions. The drive specialist also adapts the motors to individual customer requirements and applications.

ABM Greiffenberger offers motors for auxiliary units in trucks and buses as well as traction drives for use in a wide variety of electric vehicles. Krüger says: ‘For our AC drives with housings, we have optimised the cooling for longer periods of continuous performance.’ Because the drive is installed on the differential axle at a right angle to the direction of travel, the developers have adapted the ring ribs of the drive appropriately to ensure optimal air cooling. This makes these motors suitable for journeys with high load peaks and high continuous performance. Even in harsh or dirty environments, reliable operation of the on- and off-road vehicles is ensured. Depending on the motor size, peak powers of 20, 50 and 90 kW and torques of 45, 130 and 260 Nm are achieved.

Sensors monitor the motor temperature and record the speed. Speed and torque control is provided via an external AC controller. Upon request, ABM can deliver a parameterised controller as a plug-and-play solution tailored to the application and can also optionally install an electromechanical holding brake. Versions with IP 66 protection rating and UL certification can also be provided.

The drives can be used in all E-mobility applications, including utility vehicles, golf carts and agricultural machinery as well as electric trucks and on- and off-road vehicles. Traction motors for electric vehicles such as baggage tow tractors and airport ground support equipment (GSE) vehicles are additional applications.

ABM offers a platform concept with multiple options.

ABM housing motors for battery-powered vehicles ensure due to the ring-shaped design of the ribs an optimized heat dissipation.

Drive Technology for Intralogistics Applications with a Distinct Added Value

>ABM Greiffenberger will present complete drive solutions at the LogiMAT (25–27 April) in Hall 3 at Booth 3B15. In close cooperation with customers, the systems supplier tailors each solution to the customer’s application and requirements. The provider’s focus in Stuttgart will be on system solutions for intralogistics along with digitalisation and thus the company’s new inverters, amongst other things.

Drive Technology for Conveying Technology

The high-efficiency, dynamic motors in the Sinochron series are one such drive solution. Without gearboxes, they can be used as direct drives for small loads – in roller conveyors for loads of up to 180 kilograms. Owing to their special design, the permanently excited synchronous motors are perfect for operation with sensorless control. Their high power density means that ABM can make the Sinochron series extremely compact. The user can then often select a smaller motor that requires less installation space and consumes less energy. The Sinochron series offers a high system availability – an important advantage for the total cost of ownership. The drives also have a service life of up to 50,000 hours. Their properties make them suitable for applications such as roller conveyors that need to transport containers of different weights, often over distances of several kilometres.

For heavy loads – for example, for extended container conveyor systems or pallet conveyor systems – the Sinochron motors can be combined with gearboxes from ABM. Various gearbox drive unit designs including right angle, straight shaft helical and parallel shaft helical are available. With the special parallel shaft helical gearbox drive unit types FG182 and FG282 for container and pallet conveyor systems, users benefit from extremely reliable radial loads and universal mounting options. In addition, the low weight and compact dimensions make installation easier to handle.

ABM Greiffenberger will also showcase its inverter series designed especially for intralogistics applications in Stuttgart. This series is available in three sizes with power outputs of up to 2.2 kW. With the series, ABM covers all common applications in container and pallet conveyor systems. Installation is quick and easy via plug-in connections. The inverters communicate with higher-level controls using the Ethernet-enabled bus systems. At 250 per cent, the overload capacity of the frequency inverters is extremely high. The decentralised solutions lend themselves well to field applications near the motors. Motor mounting and wall mounting are possible. ABM Greiffenberger’s solutions thus cover the entire range of applications in warehouse logistics – from small roller conveyors to heavy-duty pallet conveyor systems.

System solutions for Mobile Drive Technology

As a systems supplier, ABM Greiffenberger offers all drive solutions for driving, lifting and steering forklift trucks from a single source. The motors, gearboxes and controllers comply with strict environmental requirements, are particularly safe and are extremely responsive for executing precise movements even at low speeds. These drive solutions include the two-stage bevel gearbox drive units in the TDB series. The drives come with plug-and-play capability for easy integration and are both powerful and energy-efficient. They offer high power densities and optimal efficiencies. The compact bevel gearbox drive units are available with manual or individual steering and with integrated electric steering drives. This is rounded off with redundant sensor monitoring. Altogether, this provides a fully integrated system solution to the user.

The drive specialist’s electric-steering hub-wheel drive units with controllers for automated guided vehicles (AGVs) or for forklift trucks will also be on display at LogiMAT. These extremely slim drive units are ideal for use in narrow vehicles. Electromagnetic service and parking brakes ensure maximum safety in operation. Specific sensors that record speed, rotor position and winding temperature can be used with the motor control system.

ABM will also show its compact, robust housed motors for electromobility applications in Stuttgart. The optimally cooled motors can be operated continuously for longer periods in battery-electric vehicles in harsh environments. Users have a motor platform with manifold options available to them and profit from cost-optimised system solutions that enable them to use fewer drive variants.

ABM’s new inverters with power outputs of up to 2.2 kW are used in all common container and pallet conveyor applications.

As a systems supplier, ABM Greiffenberger offers all drive systems for driving, lifting and steering forklift trucks and pallet trucks from a single source.

A modular building kit for mobile applications enables diverse and flexible drive configurations.

Housed motors for battery-electric vehicles from ABM feature optimised cooling in harsh environments.

System Solutions from a Single Source

>ABM Greiffenberger application-specific system solutions at SPS (8/11 to 10/11 in Nuremberg) at booth 3A-400 / hall 3A. The full-service provider for drive technology supplies motors, drives, brakes and electronics from a single source. The drive specialist works closely with its customers. User benefit from the high development and system expertise as well as the extensive know-how of the company. In Nuremberg the focus is on the increasing digitization, among other things.

The EuP Regulation (Energy using Products) of the European Parliament for single-phase induction motors comes into force on July 01 / 2023. Then the energy efficiency class IE2 will be mandatory for two, four, six and eight pole continuously operated single-phase induction motors with a power higher than 0.12 kW. ABM Greiffenberger already supplies energy efficient three-phase induction motors. With built-in electronics these can also be operated in the future on widely used 230V single-phase mains at any time. A single-phase motor with capacitors is no longer required. All advantages of the three-phase motors such as a higher starting torque, lower starting current as well as a lower grid load can also be used on single-phase mains. Moreover, in comparison with the single-phase version the three-phase induction motor with built-in electronics excel with compact design, higher power density and efficiency as well as an optimised quiet running.

In combination with the built-in electronics the single-phase induction motor is controlled fully electronically. A capacitor is no longer needed. This makes the drive system significantly more durable with low maintenance. Optionally, a temperature monitoring of the motor and the power section of the electronics is available.

Expansion of the Parallel Shaft Geared Drive Units by compact, two-stage Types

The system provider has expanded the existing parallel shaft gearboxes (FG series) and presents the FG182 and 282 types in Nuremberg specially for the conveyor and pallet conveyor technology in intralogistics. The extremely compact two-stage solutions offer nominal torque of 180 and 280 Nm and thanks to their gear ratio and compactness they can also be used as travel drives in lifting applications. The user also benefits from highly reliable radial loads as well as the universal mounting options such as hollow and solid shaft, shrink disc, version with and without flange. Furthermore, the low weight and the compact design enable easy handling.

New Frequency Inverter of up to 2.2 kW for Intralogistics

Applications in intralogistics are primarily controlled with frequency inverter. The inverter series for the conveyor and pallet technology is completed with two more frame sizes specially developed for this industry. Thanks to the power range of up to 2.2 kW higher loads can also be moved. Thus, ABM Greiffenberger covers all required applications.

The user benefits from the optimal control properties both with asynchronous as well as with Sinochron motors. The frequency inverter can operate the permanently excited synchronous motor without the use of sensors. This lowers the costs and increases availability.

The inverter are designed for a service life of 30,000 hours under full load and continuous operation. Pluggable connections allow an easy and quick installation. The inverters communicate with higher-level control systems via Ethernet-capable BUS systems.

With a protection class of up to IP54 and a high overload capacity of 250 percent, the frequency inverters are perfect for accelerating heavy loads. They are also suitable for use at temperatures of 30 to +40° Celsius and therefore for use in deep-freeze storage.

Systems Supplier: One single Partner for your Drive Units

As a system supplier, ABM Greiffenberger develops and manufactures application-specific and installation-optimised solutions from a predefined modular system that are perfectly tailored to the application. The specialist thus continues to pursue its goal of not only supplying high-quality and reliable drive solutions, but also supporting its customers as a development partner with engineering and manufacturing expertise. Customers receive cost-efficient complete solutions with measurable benefits.

The compact, energy-efficient three-phase asynchronous motors with single-phase fed electronics offer all the advantages of a three-phase motor when operated on a single-phase mains supply.

ABM has added two-stage compact types - FG182 and FG 282 - to its existing range of parallel shaft gear units.

Two additional frequency inverters developed specifically for intralogistics applications complete the series for conveyor and pallet technology.

The First Step into the Professional World.

>On September 1, 2022, a new phase of life began for twelve young people: they started their commercial or technical apprenticeship or dual studies at ABM Greiffenberger Antriebstechnik GmbH. With them, the number of our junior staff grows to a total of 35 trainees.

"The quality of training at ABM Greiffenberger is at a high level - this is confirmed by the recurring very good final examination performance", reports Ralph Treude, CEO of ABM Greiffenberger. "With a guaranteed job offer in one of our specialist departments, we offer all trainees a long-term perspective, which is also flanked by targeted advanced training and qualification measures."

In addition to their technical skills, the young employees are encouraged to work independently. They are their own boss when it comes to realizing their particular projects; at the same time, creativity and team spirit are also required. "Our trainees have already created, planned and realized great things. For example, they designed and built a basketball machine, an air hockey game and even a candy sorting machine," says Treude.

Apprenticeship Day at ABM Greiffenberger

We cordially invite everyone who wants to find out more about our apprenticeships and gain an insight into our apprenticeship workshop to the "Apprenticeship Day". This will take place on Saturday, October 29, 2022, at ABM Greiffenberger in Marktredwitz. Various hands-on stations and interesting discussions with our trainees and trainers await the visitors. Registrations is not required.

Apprenticeship Fairs

Our team will also be happy to answer any questions you may have at the following apprenticeship fairs:

- Apprenticeship fair in Marktredwitz (September 24, 2022)

- Apprenticeship fair in Kemnath (October 08, 2022)

Applications for the 2023 Apprenticeship

Applications for the year 2023 are already being accepted. And it's very easy: Go to www.abm-antriebe.de/karriere/stellenangebote select the desired apprenticeship, enter your data, upload your report card and CV and you're done!

From left to right:

Marc Mayer (Youth & Trainee Representative), Reimund Lork (Staff Manager), Sven Fronhöfer, Bernhard Wenning (Training Manager), Emine Akkaya, Nico Pollak, Kathrin Weiß, Baki Toy, Tim Grosser, Luca Pollak, Felix Schmelber, Willi Heinl, Niklas Schindler, Markus Nickl, Ralph Treude (CEO), Jan Tröger (Chairman of the Works Council) and Marco Meier (Vice Chairman of the Works Council) .

(Not on the picture Leon Wieland)

Drive Solutions for Mobile Applications in Material Handling

>The electrification trend is just taking off in mobile applications for material handling. Electric drives are dynamic, efficient, powerful and above all reliable. They are thus suitable for forklifts, automated guided vehicles (AGVs) and pallet trucks. ABM Greiffenberger supplies the appropriate motors, gearboxes and electronics developed and manufactured in-house – and adapted to the individual application. This makes the drive specialist from Marktredwitz a valuable partner for customers with diverse intralogistics applications.

Many things are moved in and around a logistics centre – and wherever this happens, drives are required. It starts with employees coming to work in electric buses. Lorries transport goods to the receiving point – drives for auxiliary units such as hydraulic pumps, compressors and fans are needed here. When the lorries drive up to the dock, rolling doors open and close so that the employees can load or unload. By means of pallet trucks, forklifts or AGVs, the goods are moved to pallet and accumulation roller conveyors, which bring them to the high-bay storage area. Ergonomic lift assists are used for goods handling and machines are used for cleaning the production floors. ‘We supply suitable motors, gearboxes, brakes and inverters for all these applications – from a single source,’ says Michael Lühmann, Head of Sales & Marketing at ABM Greiffenberger. ‘This makes us a systems supplier for the entire intralogistics field.’

The drive specialist offers ready-to-install plug-and-play systems available as modules within a platform concept for the mobile sector. ‘We can thus easily combine gear ratio and motor size with brakes and sensors and in this way optimise customer applications. The finished solutions can be integrated into the different vehicle types,’ reports Lühmann. This is by no means always the case on the market.

ABM Greiffenberger can completely cover the functions of traction, lifting and steering with its solutions in the mobile sector. They comply with strict environmental and emission requirements, are particularly safe and are extremely responsive for precise movements even at low speeds. ‘With this we are responding to a growing market. Because electrification is advancing more and more in mobile applications in intralogistics,’ says Michael Lühmann. Electric drive systems are more sustainable and more efficient. They run reliably and smoothly, are dynamic and durable, and offer safety. For that reason it is only logical for electric drives to be increasingly employed in a number of applications.

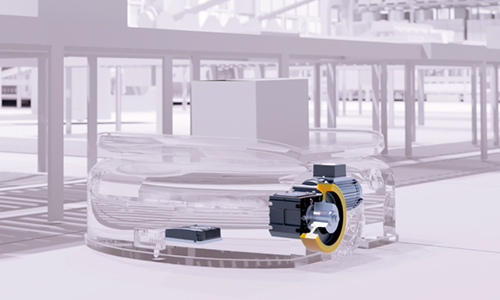

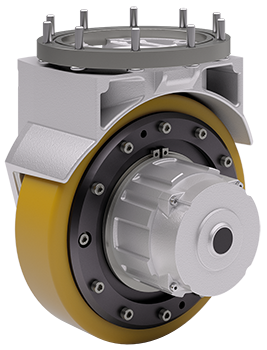

Hub wheel drives with electric steering

The drive specialist offers three gearbox types for mobile applications – including the robust TDH series hub wheel drives. This type of drive is extremely compact because the drive components are integrated into the drive wheel. The user profits from high static and dynamic wheel loads. Thanks to high wheel torques at low speeds, the user can precisely manoeuvre and drive up inclines with, for example, pallet jacks, aerial work platforms, AGVs or sweeper/scrubbers. ‘We also offer the hub wheel drive with electric steering,’ says Dipl. Ing. Mayk Krüger, Head of Mobile Drive Technology. With its low installation height, this version is ideal for forklifts and automated guided vehicles. The user benefits with the hub wheel drive with electric steering from a precisely controllable and efficient AC motor technology. It brings a torque of up to 300 Nm to the wheel and has a drive torque of 360 Nm. The redundant steering sensors provide for precise steering. Moreover, the drive is durable, maintenance-free and highly loadable.

Bevel Gearbox Drive Units: Innovative platform concept

With the bevel gearbox drive units in the TDB series for wheel diameters of 230 to 254 mm, the systems supplier has efficient components featuring high performance and low energy consumption in its portfolio. The ready-to-install systems are modularly designed and are available as a platform concept. The complete solution comprising the motor, gearbox and sensors can easily be integrated into different vehicle types. In industrial trucks the TDB series bevel gearbox drive units provide high climbing performance and acceleration. They offer responsive and dynamic steering over the entire speed range.

The bevel gearbox drive unit is available in three versions – for example, with an integrated steering drive. The traction motor is vertically mounted in the fixed version. The operator profits from, amongst other things, redundant steering monitoring, maximum integration and excellent ride comfort with high safety.

ABM Greiffenberger also supplies the bevel gearbox drive unit for manual steering. The vertical mount of the traction motor in the rotating version is designed for direct drawbar mounting. This robust and durable solution features space-saving installation.

‘Application-specific steering is also possible; customers can also combine the TDB bevel gearbox drive units with their own steering drives,’ says Mayk Krüger. They are thus suitable for electric power steering systems and can be controlled via spur gear. A zero position sensor can optionally be attached for calibration of the steering positions.

Speed recording in this series is done via an incremental encoder with up to 64 pulses per revolution. There is also an option to use the AC technology with regeneration capability. An electromechanical holding brake is integrated for parking and emergency stopping.

Parallel shaft gears: Quiet and efficient

The TDF series helical gearbox drive units offer an especially high efficiency, low wear and quiet running even at high loads. ‘We achieve this via the high-contact-ratio helical gear technology,’ explains Lühmann. The gearboxes are suitable for use in pallet jacks and three-wheel forklifts, for example. ABM manufactures the gearboxes from die-cast aluminium. Thus customer-oriented solutions can be provided at a good price-to-performance ratio. The design and the matching of the material to the application make sizes 200 mm and 230 mm light and stable. Speed recording is done via an incremental encoder with up to 64 pulses per revolution.

Systems supplier with high level of development expertise

ABM Greiffenberger scores points both with its extensive know-how and experience in the development of application- and customer-specific drives and with its platform concept, which ensures that customers quickly receive cost-optimised solutions. ‘However, we can also specifically address customer requirements,’ says Krüger. ‘Thus we are not a standard supplier and offer our customers a measurable added value.’

One example of an individual development is an electric differential axle for forklift trucks and transport systems. Precisely adapted to the application, the differential axle has optimised interfaces and can thus easily be implemented into the vehicle.

ABM supplies all products, including motors and gearboxes as well as suitable electronics, from a single source. Even complex prototypes can be produced at short notice with additive manufacturing.

‘Our drives offer high performance and system availability,’ stresses Lühmann. This is especially important in material handling because the vehicles are often used in two- or three-shift operations. Reliability is extremely relevant here. Operators therefore rely on drives that are maintenance-free, robust and durable. ‘We consistently pursue our goal of not only delivering high-quality drive solutions, but also supporting our customers in the capacity of a partner with engineering and manufacturing expertise,’ says Michael Lühmann.

The platform concept of the TDB bevel gearbox drive units offers users numerous options:

Depending on the application case, integrated, manual or application-specific steering can be selected.

Plug-and-play for automated guided vehicles – the efficient TDH230i hub wheel drive with electric steering enables precise and safe manoeuvring.

Electric differential axle for forklift trucks and transport systems – an individual drive system specially adapted to the specific application.

How ABM Greiffenberger Drives the Intralogistics World

>ABM Greiffenberger has suitable drives for all mobile and stationary applications in logistics centres. In close partnership with customers, the one-stop provider for intralogistics delivers both optimised modular system solutions and individual solutions with maximum added value for users. Visitors can find out about the powerful drives in Stuttgart) in Hall 3 at Booth B15.

Many things are moved in and around a logistics centre – and wherever this happens, drives are required. It starts, for example, with mobile applications such as electric buses that drive employees to their place of work or lorries that transport goods to the receiving point – drives for auxiliary units such as hydraulic pumps, compressors and fans are needed here. When the lorries drive up to the dock, rolling doors open and close so that the employees can load or unload. By means of pallet trucks, forklifts or automated guided vehicles (AGVs), the goods are moved to container and pallet conveyors, which bring them to the high-bay storage area. Other devices and machines, such as ergonomic lift assists for handling the goods and machines for cleaning the floors in the building, are also deployed. ABM Greiffenberger offers suitable motors, gearboxes, brakes and inverters for all these applications – for either mains or battery power supply.

These drive solutions include the Sinochron motor series, which visitors can find out about at the trade fair booth. The permanently excited synchronous motors are perfect for operation with sensorless control thanks to their special design. The advantages offered by synchronous motors are a high power density and a compact size. With efficiencies of more than 90 per cent, these motors score points in intralogistics applications in which drives are only operated at part load as well as in auxiliary units in lorries and buses.

ABM Greiffenberger has added compact and powerful liquid-cooled motors to its efficient drive technology offering. The motors possess a high thermal stability and offer exceptional protection with ratings of up to IP6K9K. They can be controlled via inverters and can be attached to all ABM helical, parallel shaft and angular gearboxes with little effort. They are ideal in areas such as mobile drive technology, where they are used, for example, as aggregate and traction drives in electric vehicles and construction machines.

Reduced Complexity

ABM offers suitable inverters that are optimally matched to the respective drive systems for all applications. They meet controllability, networking, digitalisation and connection technology as well as other requirements.

Wheel Hub Drive for AGVs – Now also with Electric Steering

ABM will present another innovation with the wheel hub drive with electric steering for AGVs and forklifts. It has a drive torque of 360 Nm; the integrated electric steering brings a torque of up to 300 Nm to the wheel. Users benefit from a precisely controllable and efficient AC motor technology. They receive complete solutions from a single source and only have to take care of the interface for the drive technology.

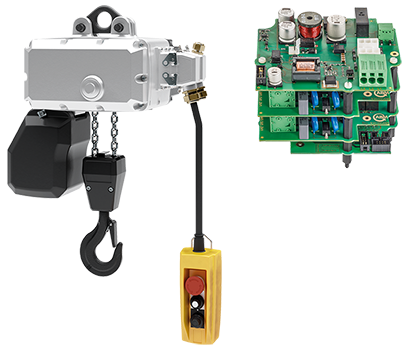

Chain hoists with integrated electronic control

The powerful chain hoists will also be presented at LogiMAT. They are modularly designed and provide reliable overload protection thanks to the friction couplings. The integrated electronic control is new. Via plug and play technology, the operator can easily extend the basic version to include the travel function. The new solution from ABM Greiffenberger is particularly long-lasting – wear of switching contacts does not occur. The corrosion-resistant and robust chain hoists also operate reliably in harsh environments. High-quality helical gearing enables quiet running and lowers noise emissions.

Systems supplier: One Partner for Intralogistics

ABM Greiffenberger is a systems supplier for all applications in intralogistics and develops customised, installation-optimised solutions that are optimally tailored to the respective applications. With this, ABM maintains its goal of delivering high-quality, reliable drive solutions and supporting its customers in the capacity of a partner with engineering and manufacturing expertise.

![]()

The advantages offered by synchronous motors are a High power density and compact size with efficiencies of 90 per cent and higher.

The trade fair offering will also include reliable and energy-efficient chain hoists with integrated electronic control.

The efficient TDH230i wheel hub drive is now also available with electric steering.

KYBURZ Switzerland AG relies on the know-how and drive technology of ABM Greiffenberger for its electric vehicles

>KYBURZ Switzerland AG with registered office in Freienstein near Zurich in Switzerland is an international leader for high-quality mobility and transport solutions used e.g. by postal operators for delivery of letters and parcels. When it comes to drive technology, the provider relies on the comprehensive support of ABM Greiffenberger, from concept to series production. ABM supplies everything from a single source.

Martin Kyburz founded KYBURZ Switzerland AG in 1991. Today, with 150 employees the company is one of the leading manufactures for urban delivery vehicles, which thanks to automatic parking brake and reverse gear arrive at their destination safely and quickly even in wintry conditions. This includes the KYBURZ DXP. The E-Mobile fleet combines the efficiency of a two-wheeler with the safety and stability of a three-wheel vehicle. DXP is used by postal operators in various countries such as Germany, Finland or Austria, as well numerous cities such as Winterthur or Montreux. However, postal and logistics companies are not the only ones relying on this environmentally friendly vehicles, the electric sport cars for leisure sector are also extremely popular and ensure lots of driving pleasure. That is why, among others, the Swiss have developed the eRod, an electrically powered racing car approved for the road.

“We offer a comprehensive service package”, says Daniel Weber, Head of Development at KYBURZ. “We develop, produce vehicles and take care of the after sale service. We also take them back after being used, process them or take care of their recycling”. Currently, over 23,000 of these electric vehicles are on the roads worldwide. Apart from the USA, the company is active in all markets worldwide.

Required: High-Performance and Efficient Drives

Users have high expectations. Especially postal services, which have to deliver their shipments quickly and reliably, require vehicles that are efficient, environmentally friendly, reliable and inexpensive to maintain. This places particularly high demands on the drives. Because the postman must be able to manage steep streets with his fully loaded vehicle and be able to accelerate at all times. Since these vehicles are used on daily basis, both acceleration and range play a major role. This requires motor performance and efficiency.

KYBURZ Switzerland AG turned to ABM Greiffenberger to manage this balancing act, this was in October 2011. As a full-service provider, the drive specialist with registered office in Marktredwitz in Upper Franconia develops and manufactures systems for stationary and mobile applications which are installed e.g., in logistics in conveyors, hoists or forklifts. In addition to modular system solutions, ABM Greiffenberger also impresses with customer and application specific drive solutions that ensure customers measurable added value. ABM works closely and in partnership with the customer. “Even before the turn of the millennium we had started to transfer our know-how from battery-powered applications to E-Mobility. Even back then we were able to implement the first customer-specific projects”, reports Jürgen Schliermann, Head of Mobile Drive Technology Development at ABM. “We recognise new trends early on - this is important, especially in a future-oriented industry such as the electric mobility. We take this into account thanks to our comprehensive development and production capabilities.”

High Acceleration from Standstill

“We were looking for a reliable partner for our ever increasing quantities and for the growing demands of the users”, explains Daniel Weber from KYBURZ. “We were familiar with the high level of expertise of ABM and the good reputation of the supplier.” The drive specialist supplied the AC end shield motors for the DXP series delivery vehicles. Weighing only around 22 kilograms, these powerful three-phase asynchronous motors are quiet, environmental friendly and optimised for the stressful stop-and-go operation. They impress with their high acceleration capacity even from the standstill position, just the right one for these applications. “The weight-optimised AC end shield motors are also robust, durable and with their special design without housing they are suitable for applications with high load peaks and high dynamics”, explains ABM expert Schliermann. Heat generation is a major issue with high torques and low speeds. This challenge can be managed with the ABM drive.

It was also important for KYBURZ to have a drive which requires little or no maintenance. In addition, the motor draws the energy from maintenance-free lithium iron phosphate batteries. External drive controllers assume the power supply and speed / torque control. Thanks to the optimised interaction with the controller the system is very well regulated, ensuring high level of power density. “We can deliver a light, efficient and compact drive that optimally accelerates, provides a good driving dynamic and therefore also achieves a long range”, says Schliermann.