- 输送和物流

叉车,物料搬运,自动导引车,桥式起重机 - 电动车辆

电动车,商用车,电动船舶,高空作业平台,扫地机/洗地机,地勤支持设备 - 农业和建筑机械

农业和建筑机械,建筑起升机,起升辅助工具 - 可再生能源

生物燃料供暖系统,风力发电 - 工业和机械/设备制造

汽车安全和检测技术,纺织机械,建筑服务,医疗技术,机床,真空泵和空压机,其他应用 - 定制化解决方案

精工系列

新闻联系人

联系我们

我们的媒体联系人很乐意为您提供帮助。 请与我们联系以获取您的

出版物以及与ABM相关的问题的答案。

ABM Greiffenberger Antriebstechnik GmbH

Dagmar Koziel | PR & Marketing

Friedenfelser Straße 24

95615 Marktredwitz | 德国

电话: +49 9231 67-6387 发送邮件

展会 & 活动

Rebuild Ukraine - International Trade Fair for Reconstruction, Energy Efficiency and Modernization of Ukraine

>Together with our sister companies from the senata Group, we will be exhibiting at the 5th International Exhibition and Conference ReBuild Ukraine: Construction & Energy.

You'll find us in Hall 4 / Booth D2 – We look forward to meeting you!

新闻

ABM Supports Youth Work of MSC Marktredwitz

>ABM Greiffenberger Antriebstechnik GmbH expresses its gratitude to MSC Motorsportclub Marktredwitz e.V. with a donation for their excellent support during the apprentice event “WITRON meets ABM” in November 2025.

On this occasion, around 50 apprentices from the WITRON Group in Parkstein visited ABM in Marktredwitz. Together with our ABM apprentices, they spent a day full of exciting insights – both into ABM’s production and into the new EDEKA logistics center in Marktredwitz. There, WITRON systems are used that are equipped with ABM drive solutions. The day offered intensive exchange and hands-on experiences with a strong connection to the region and to one of Germany’s most significant logistics projects.

For the activity day, the MSC provided its petrol-powered go-karts, giving the young participants an extraordinary driving experience. Another highlight was the electrically powered e-kart, which our ABM apprentices designed and built independently – a project that demonstrates technical commitment, creativity, and team spirit.

As a token of appreciation, ABM presented a donation cheque of 500 euros in support of the MSC’s youth work.

“As a company based in Marktredwitz, it is of central importance to us to support regional partners. Local, targeted assistance is close to our hearts – we want to take action where our support truly makes a difference and creates positive momentum for young people,” says Torsten Müllner, CEO of ABM Greiffenberger Antriebstechnik GmbH.

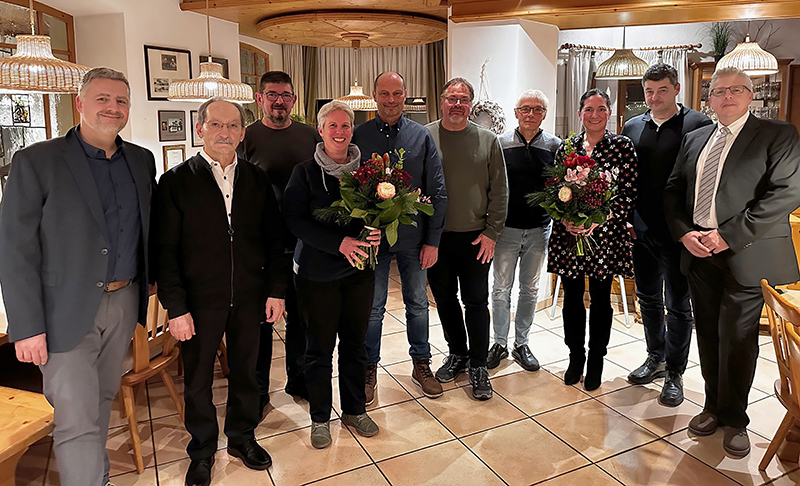

Cheque presentation to representatives of MSC Marktredwitz

From left: Roswitha Gerstner, Heinz Pogrzeba, Klaus Gottfried, Karin Gottfried, Andreas Weinberger (all MSC), Torsten Müllner (Managing Director, ABM), Christina Günther (Head of Human Resources, ABM), Eduard Eckenberger (Trainer Electrical Engineering Department, ABM)

ABM Celebrates 570 Years of Employee Service

>On Thursday evening, December 4, 2025, ABM Greiffenberger Antriebstechnik GmbH honored the decades-long commitment of its employees at the “Zum Hirschen” country inn in Rodenzenreuth. A total of 21 colleagues were recognized – together they represent an impressive 570 years with the company.

In his speech, CEO Torsten Müllner emphasized the importance of long-serving employees:

“In challenging times like these, this celebration is far more than a formal gesture. It shows how strongly ABM is supported by expertise, loyalty, passion, and experience. People who take responsibility over many years give our company a face and an identity. For this, I thank you personally and on behalf of the entire company.”

Alexander Schäffler, Head of Operations, and Works Council Chairman Jan Tröger also expressed their gratitude to the colleagues and highlighted the great value that long-standing experience brings to day-to-day operations and the company’s development.

Eighteen employees were honored for 25 years with the company, and three colleagues were recognized for an impressive 40 years of service at ABM.

The evening offered space for many personal conversations, shared memories, and reflections spanning several decades of working together. With this strong sense of continuity within the team, ABM Greiffenberger looks confidently toward future challenges – well positioned through experience, dedication, and unity.

Left to right: Jan Tröger (Works Council Chairman), Torsten Müllner (CEO), Andreas Forster, Stephanie Adler, Marco Meier, Ewald Kastner, Jürgen Ehmes, Ayhan Budan, Jürgen Simmler, Thomas Schüler, Matthias Bähr, Sabine Karawassilis, Sandro Möse, Kay-Peter Huber, Mehmet Erduran, Lars Fischer and Alexander Schäffler (Head of Operations)

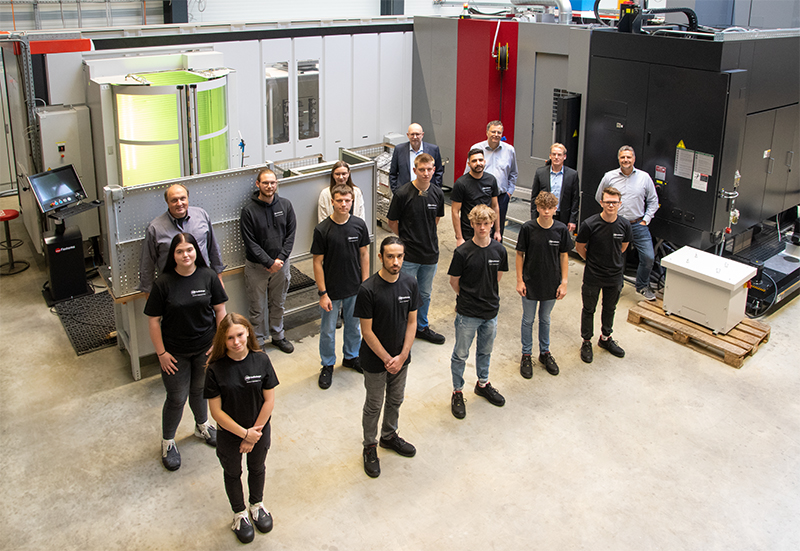

Apprenticeship Day connects Two Strong Partners

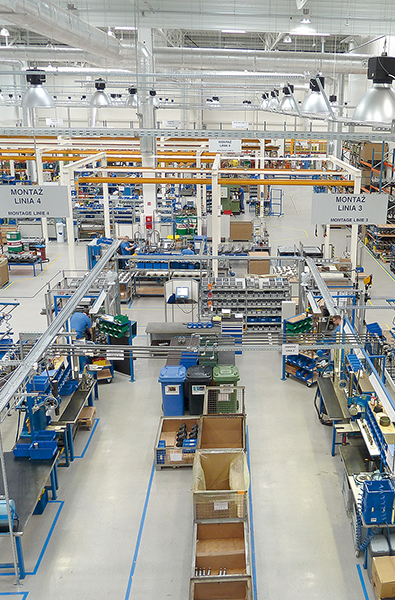

>When young people experience what modern industry can achieve, enthusiasm for future-oriented professions begins to grow. That is exactly what happened on Monday, when 50 apprentices from the WITRON Group in Parkstein visited ABM Greiffenberger GmbH in Marktredwitz. Together with ABM’s own apprentices, they spent a day full of insights, exchange, and hands-on experiences – with a strong link to the region and to one of Germany’s most significant logistics projects currently underway.

Insight into Precision and Performance from Marktredwitz

To start the day, Sales Director and Managing Board Member Alexander Hecht warmly welcomed the guests and introduced the company. ABM Greiffenberger develops and produces customized drive systems – consisting of motors, gearboxes, inverters, and complementary components such as brakes. These solutions are used in a wide variety of applications, including conveyor technology, material handling, and mobile working machines.

A Fascinating Look Inside the New EDEKA Logistics Center

The next stop was the new EDEKA logistics center near Marktredwitz – a project that has attracted attention far beyond the region. The facility is one of the most modern of its kind and will secure numerous long-term jobs in northeastern Bavaria. The reason for the visit: Many of the systems operating there are WITRON solutions powered by ABM drives. On site, the apprentices were able to see how automated processes, sensors, and energy-efficient drive units work together seamlessly to ensure smooth logistics operations – high-tech with a regional signature.

An Energetic Finale with a Self-Built Electric Go-Kart

In the afternoon, another highlight awaited the group: At the “Bahneinzelgrund” site on Rößlermühlstraße in Marktredwitz, participants tested an electrically powered go-kart that ABM apprentices had built as their own project – naturally equipped with an ABM drive. The vehicle impressively combines enthusiasm for learning, craftsmanship, and technical understanding. During a small race, the fastest driver was crowned before everyone wrapped up the day in high spirits.

A Day That Shows What Is Being Created Here

“We want to inspire our young talent and show what can be achieved here on site with expertise and innovative strength,” says Alexander Hecht. “As a company from Marktredwitz, we are proud to contribute to the region’s technological development together with partners like WITRON. The visit to the EDEKA logistics center once again made it clear: When technology, automation, and strong drive solutions come together, something remarkable is created. For the apprentices, it was a day full of new experiences – for us, a day that shows: Our region has a strong future.”

With the exchange between WITRON and ABM, two leading industrial companies from the Upper Palatinate are strengthening not only their partnership but also the appeal of technical professions in the region. Young professionals are able to experience first-hand just how much innovation and expertise are rooted in northeastern Bavaria – and that modern industrial work is anything but grey and monotonous.

ABM Celebrates 405 Years of Employee Service

>On Thursday, November 28, 2024, a special event took place at the "Zum Hirschen" country inn in Rodenzenreuth: ABM Greiffenberger GmbH honored long-serving employees for their impressive loyalty and dedication to the company. Together, they celebrated an extraordinary total of 405 years of service.

In his welcoming speech, Torsten Muellner, CEO of ABM, emphasized the importance of long-serving employees for the company’s success:

"No company can be strong if it cannot rely on strong employees. With their expertise, passion, and loyalty, our anniversary employees have made a significant contribution to making ABM what it is today. We would like to sincerely thank them for this."

Jan Troeger, Chairman of the Works Council, also acknowledged the achievements of the jubilarian employees and highlighted the close relationship that has developed over the years between the staff and the company.

The awards ceremony included three employees with 25 years of service, seven employees with 40 years of service, and one particularly remarkable achievement: Mr. Anastasios Peponis celebrated an incredible 50 years at ABM—a milestone that is rarely reached.

After a festive dinner, the management and works council presented personal gifts to the jubilarians, accompanied by a review of their professional careers. The evening ended with a group photo and a relaxed gathering, during which anecdotes from many decades were shared.

ABM is proud of the commitment and loyalty of its employees—an achievement that radiates far beyond the company’s borders.

From left: Jan Troeger, Anastasios Peponis, Mario Ibanez, Beate Zehrer, Volker Michel, Mathias Friedrich, Andreas Nickl, Martina Bartmann, Michael Pollak, Torsten Muellner

Three Young Talents Begin Their Careers at ABM

>Under our motto “Together we put ideas into gear”, ABM welcomed three new trainees on September 02, 2024. With these new additions, we are currently training a total of 27 specialists.

The trainee’s journey began with a welcome day, during which their parents also participated in a factory tour to learn and have a proud feeling of where their loved ones will spend their future. Further training sessions and induction activities are scheduled for the coming weeks. “Comprehensive support and targeted encouragement during training are the key to a successful development of our young specialists,” emphasizes Torsten Muellner, CEO at ABM.

“We place great importance on fostering a strong sense of community,” explains Christina Guenther, Head of Human Resources at ABM. “In addition to varied training, our apprentices can look forward to the annual training trip in the fall - a highlight that strengthens team cohesion and encourages networking across the trainees.”

Get to know us

Would you like to find out more about your opportunities at ABM and the benefits we offer? Then visit us at one of the following training fairs and get all the information you need first-hand:

- September 28, 2024 – Fichtelgebirgsrealschule Marktredwitz

- October 19, 2024 – School Center Kemnath

We also offer orientation days and student internships to help you explore your career options. Visit our careers portal at www.abm-drives.com for all the details.

Applications for the 2025 Training Year

We are now accepting applications for 2025. The process is simple: choose your desired apprenticeship at https://www.abm-antriebe.de/en/careers/job-offers, enter your details, upload your certificates and CV—and you're in!

From left to right:

Marc Mayer (Youth & Trainee Representative), Marco Meier (Vice Chairman of the Works Council), Eduard Eckenberger (Trainer Electrical Engineering), Jan Tröger (Chairman of the Works Council), Simon Pöllath, Emilian Gschwend, Christina Günther (Head of Human Resources), Torsten Müllner (CEO) und Sebastian Prechtl (Training Manager)

Not in the picture: Our new apprentice Younes Achernan

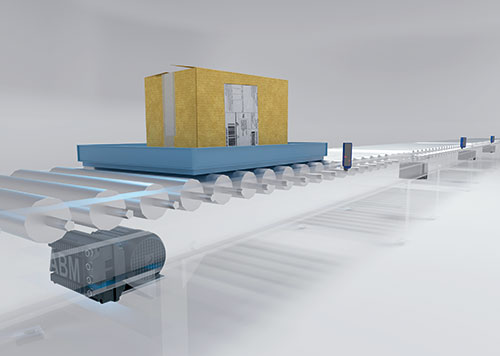

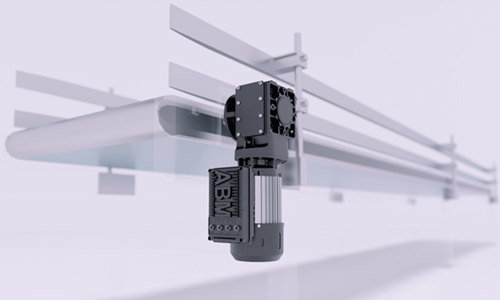

Efficient and Economical Horizontal Movements

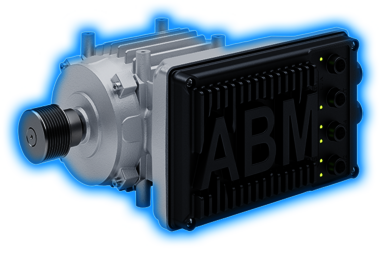

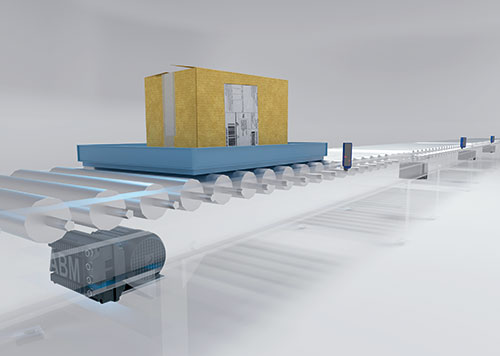

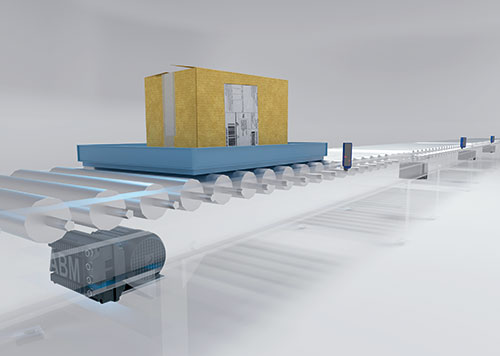

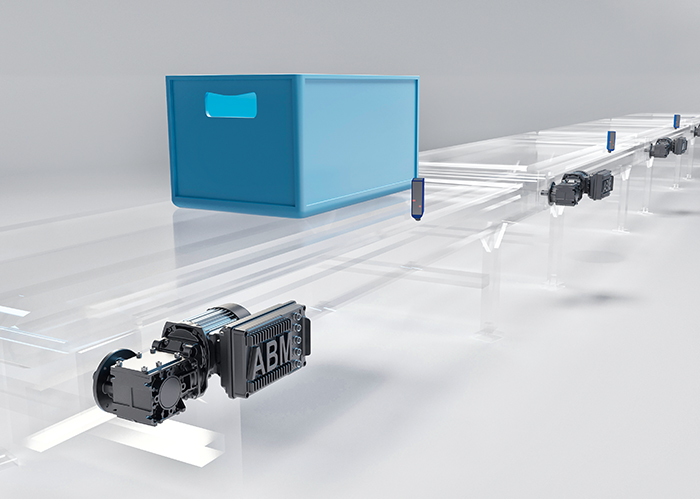

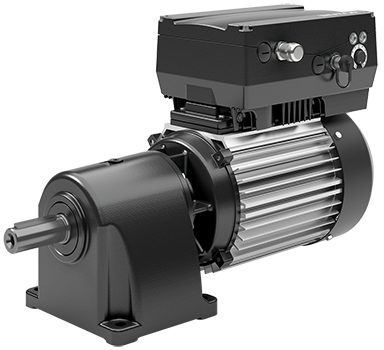

>One of ABM Greiffenberger's product innovations is the highly integrated drive system for roller conveyors. During development, the specialists focused on making it compact, efficient and economical. This provides users with a particularly powerful and productive solution for horizontal conveyor technology.

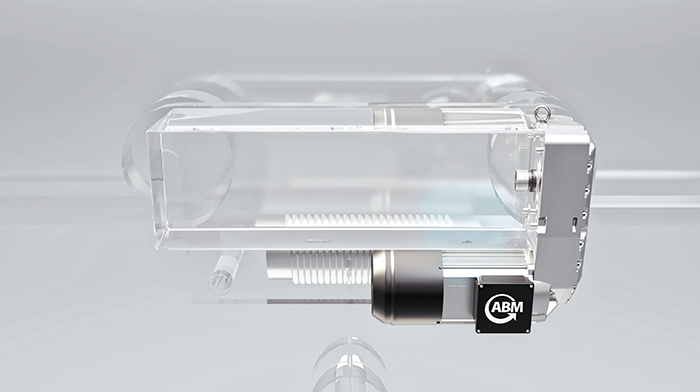

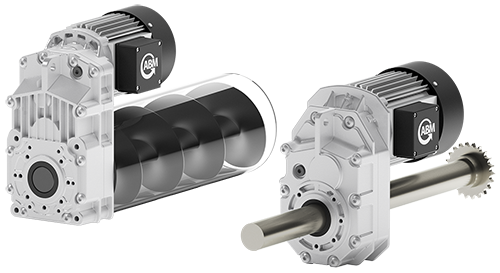

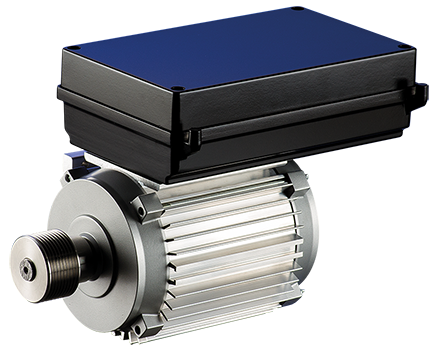

The drive system for roller conveyors consists of a synchronous motor with an integrated controller. It has a rated output torque of 4.5 Nm with almost double the overload capacity and can move loads of up to 180 kilograms. The direct drive is a complete one-piece motor-inverter unit. This universally applicable new development is suitable for a wide range of container conveyor technology applications, including roller conveyors and curved belts.

One for All

ABM covers all common requirements in container and pallet conveyor technology with one motor. This allows system integrators to reduce complexity and the number of variants, which has a positive effect on overall costs. The drive can be easily integrated into specific application thanks to the various mounting options. Due to the high temperature range of -30 to +40 degrees Celsius, it is also predestined for deep-freeze storage.

ABM has optimized the motor technology and thus increased the energy efficiency to a maximum – this reduces the CO2 footprint. The overall system is also sustainable and resource-saving thanks to an optimized use of materials. Another advantage for the operator is the rapid return on investment: the reliable and efficient performance of the sensorless controlled drive also saves significant costs. As a result, this system solution works without the encoders, which are cost-intensive and prone to fail.

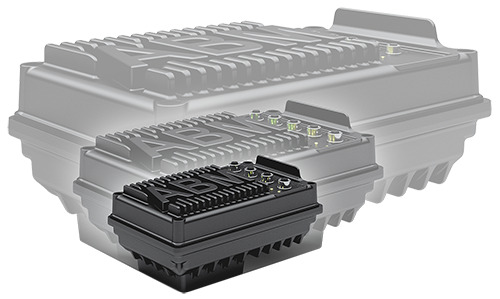

The drive specialist has designed all of the controller's connections to be pluggable. This significantly reduces the installation effort. The controller is easily controlled via the integrated multi-protocol Ethernet interface. System updates are also readily available via this interface. There is also a predictive service module: Machine-to-machine communication enables predictive maintenance and therefore smooth operation of the system - the user benefits from very high availability.

Also for high loads

As an intralogistics partner, ABM also offers complete system solutions for extended bin or pallet conveyor technology, i.e. for transporting loads of up to one ton per load carrier: Intelligent combinations of motor, gearbox and controllers from the modular system reduce the number of variants here too. The motors can be combined with angular, helical and parallel shaft gearboxes. This allows users to minimize their stock and still have the right component on hand quickly when required, another substantial benefit.

The new highly integrated drive system for roller conveyors impresses with maximum efficiency and economy.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

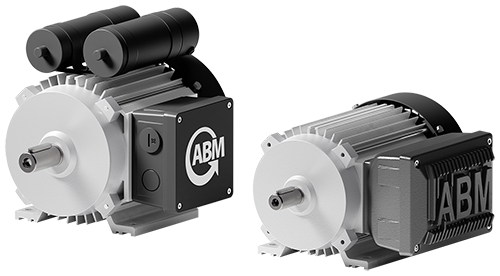

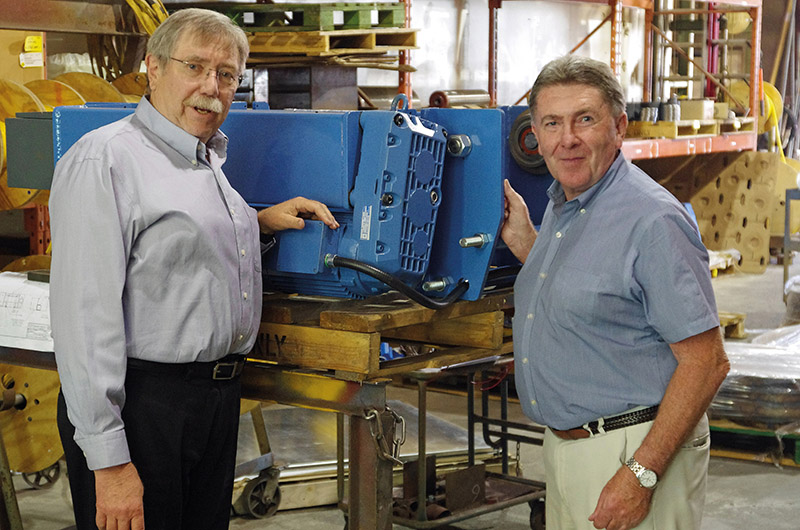

Measurable Customer Benefits for a Competitive Advantage

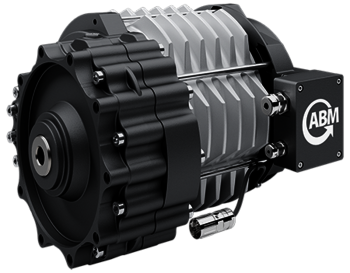

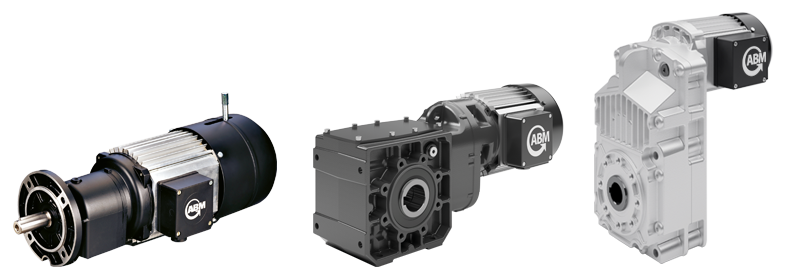

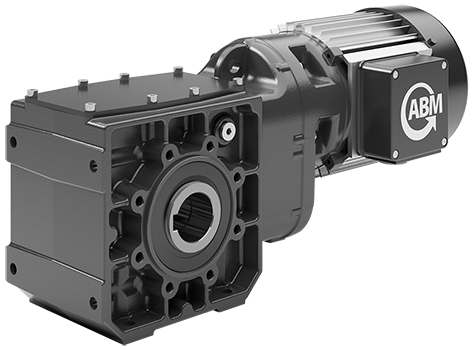

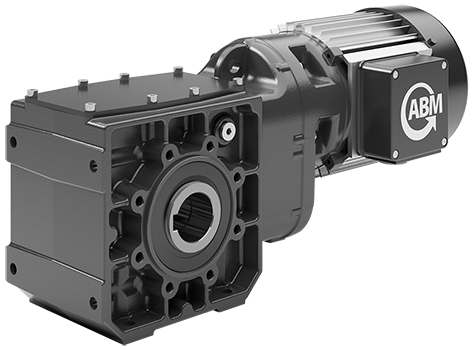

>In every industry - often even within a product range - very specific requirements apply to the drive solutions used. Only when these are fully integrated, it is possible to achieve the optimum level of performance and efficiency. With its comprehensive know-how, ABM develops and manufactures electric motors, gearboxes and controllers. With its broad product range and high level of manufacturing integration, the full-range supplier finds the optimum solution for every requirement.

ABM defines performance not only just by torque, but above all by the measurable usefulness to customers. With its engineering expertise and state-of-the-art testing technologies, the drive specialist develops a broad technology platform for motors, gearboxes and controllers. Using an intelligent modular system, the supplier can adapt the various gearbox designs to the respective application and provide the user with a quickly available and cost-efficient drive solution in terms of functionality and efficiency. ABM also offers concepts adapted to specific industries. ABM is also a development partner for individual system solutions that are precisely tailored to a specific application.

These include, for example, generators that are installed in a truck axle module. This module generates energy while the trailer is in motion in order to supply cooling units with CO2-neutral and quiet electricity. The two built-in generators provide double the power and reliability. ABM has designed the housing specifically for the application to ensure optimum air cooling. This solution is designed in protection class IP6K9K. This means that the housing is dust-tight and can be cleaned under high pressure. The generators are optimized and compactly housed in the axis. Durable, robust and efficient, they form a reliable basis for sustainable and powerful energy generation.

ABM has developed another solution for medical and rehabilitation technology. Special drives are often used in these areas, which have to combine many functionalities in a very small space with very high demands on safety, precision, comfort and reliability - for example in stair lifts. In addition to the travel movement along the stairs, seat leveling is also required to compensate for different gradients. The two functions of travel and leveling are conveniently located in one drive unit. And because the housing can absorb external forces, this solution requires fewer components. The drives also run particularly quietly and smoothly. The drive specialist supplied a compact unit comprising motor, gearbox and controller from a single source.

For highly efficient pump systems, the ABM engineers designed a pump and gearbox housing from just one part. The drive solution is precisely adapted to the required function, interfaces are eliminated and the installation space is used to the maximum. ABM thus demonstrates a very high level of system integration. The pump can be operated using a special eccentric mechanism. The combined gear and pump lubrication ensures sustainability. This unit is also easy to service and maintain.

ABM has also tailored compact and safe drives for construction elevators precisely to their function. The interface is designed specifically for the application. Because load-bearing and guiding elements are integrated into the gearbox housing, the drive not only moves the construction elevator, but also ensures that the cage is held securely and runs reliably with guidance. The drive can be installed quickly and easily thanks to plug-and-play. And because ABM was able to reduce the number of components, the user saves costs.

Customized system solution for the electrification of a truck refrigeration unit: maximum emission reduction and efficient use of kinetic energy when driving and braking.

Precise, convenient and reliable: Drive units for stairlifts.

Compact and safe drives for construction elevators: The gearbox housing incorporates load-bearing and guiding elements.

Focus on Sustainability and Efficiency

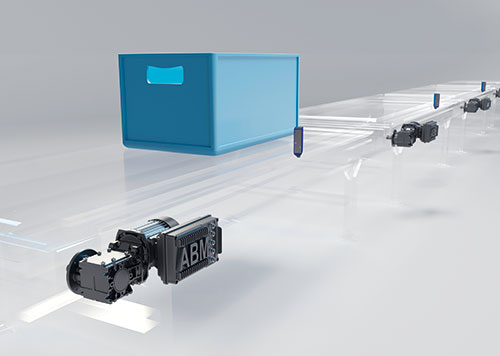

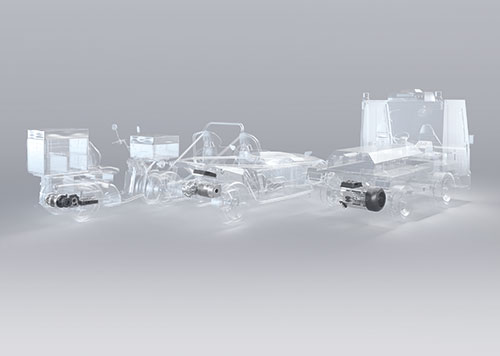

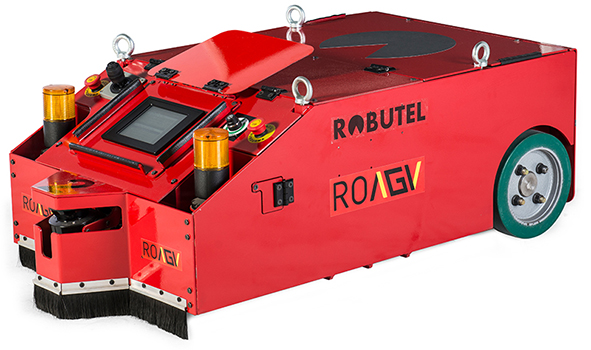

>ABM will present complete drive solutions for a wide range of intralogistics applications at the upcoming LogiMAT in Stuttgart (19–21 March) in Hall 3 at Booth 3B15. The system supplier tailors the drive solutions in close cooperation with the customer to his unique application and requirements – while maintaining a strong focus on ensuring sustainability and efficiency of the proposed drive package.

As a full-service provider, ABM develops and manufactures drive systems for stationary and mobile applications in all areas of intralogistics. In electric buses or trucks they are used, for example, for auxiliary units such as hydraulic pumps, air compressors and cooling fans. They are also installed in pallet trucks, forklift trucks and automated guided vehicles (AGVs) as well as in container and pallet conveyors, cranes and industrial doors. The system solutions consist of motors, gearboxes, brakes and inverters – selectively for mains or battery power supply.

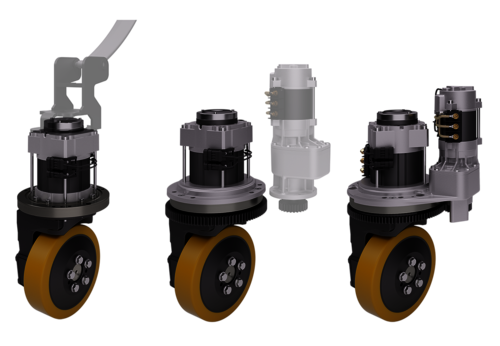

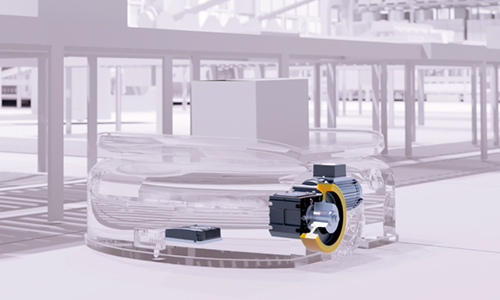

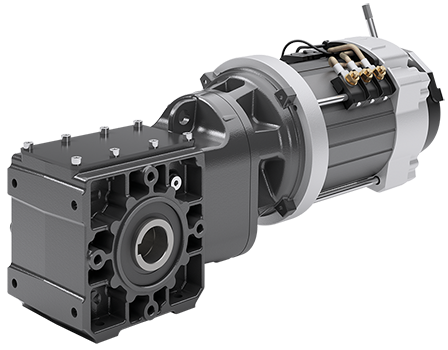

All Drive Components for Traction, Lifting and Steering

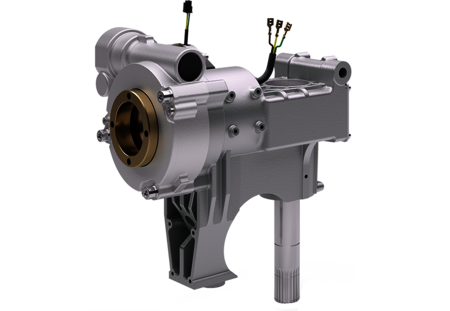

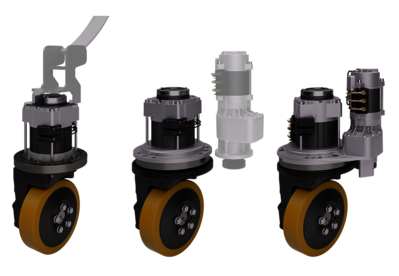

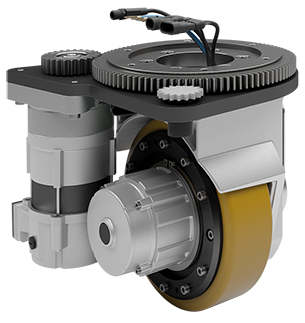

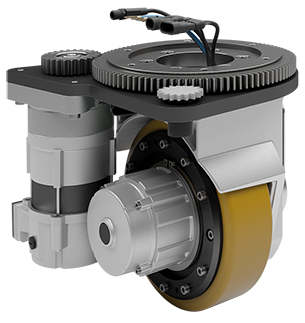

ABM offers all drive solutions for driving, lifting and steering of forklift trucks as a single source. The motors, gearboxes and inverters comply with strict environmental requirements, are safe and are extremely responsive for precise movements even at low speeds. One of the available drive options are the two stage bevel gearbox units of the series TDB. These drive units come with plug-and-play capability for easy integration and are both powerful and energy-efficient. They offer high power densities at optimum efficiencies. The compact series is available with manual or individual steering as well as with integrated electric steering drive.

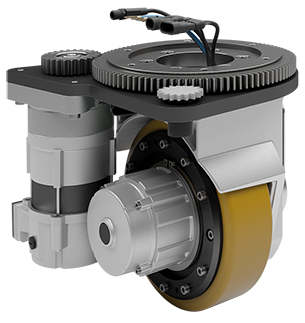

The drive specialist will present the TDH series electric-steering hub-wheel drive units with inverters for AGVs, pallet jacks, cleaning machines, industrial trucks or track-bound vehicles. These units are compact, robust and capable of handling high static and dynamic wheel loads. For the motor control specific sensors that record speed, rotor position and temperature are included.

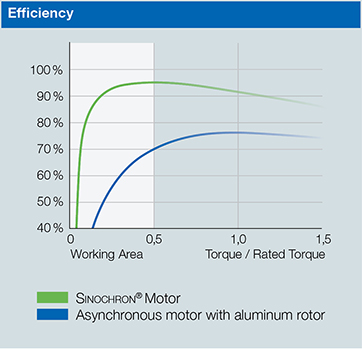

Driven with High Energy Efficiency

The wide product range includes induction motors as well as the sustainable and high-efficiency Sinochron motors. Because Sinochron motors already meet the requirements of premium energy efficiency class IE5, users do not have to worry about compliance with legal regulations. The synchronous motor has a compact design and can easily be integrated into systems. With the unique feature sensorless control, the inverter calculates the rotor speed and the instantaneous rotor angle from electrical feedback. With this data, the currents for torque generation can be fed precisely to the motor. The motor can be optimally controlled over a wide speed range with a high starting torque – without the need for expensive sensors.

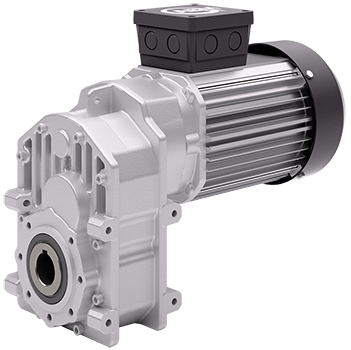

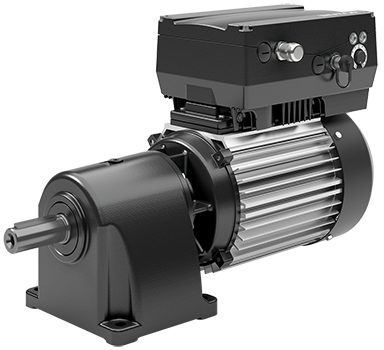

The comprehensive product range also contains helical gearboxes with torques from 30 to 2000 Nm, parallel shaft gearboxes with 50 to 2300 Nm and angular gearboxes with 60 to 450 Nm. They can be supplied with flanges, solid shafts or hollow shafts. Also available are brakes and sensors.

Via an intelligent modular system, the provider can adapt the various gearbox configurations to the respective application and rapidly deliver a drive solution with high cost efficiency with regard to functionality and efficiency. ABM also offers industry-tailored concepts. For special applications, ABM can also develop completely new system solutions as partners in close cooperation with customers.

Highly Integrated Drive System for Accumulation Roller Conveyors as a Trade Fair Premiere

One innovation example is the highly integrated drive system for accumulation roller conveyors. During development focus was placed on compactness, maximum efficiency and cost. Efficient and dynamic motors are installed as direct drives for small loads. For higher loads – such as in pallet conveyors – the drives can be combined with angular, helical or parallel shaft gearboxes. Added to that is an inverter series designed especially for intralogistics applications. This series is available in three sizes with power outputs of up to 2.2 kW and a high overload capacity of 250 per cent. With the series, ABM covers all common applications in container and pallet conveyor systems. And because most drives in intralogistics only operate at part load, the Sinochron motor with sensorless control are the perfect match.

Sustainability Award

With the ePower axle module from BPW Bergische Axis KG, ABM will present an example of sustainability and efficiency in Stuttgart. The axle module generates energy when the trailer is in motion and uses it to power cooling units quietly and in a CO2-neutral manner. Two generators from ABM double the power and make the system fail-safe. The overall system, awarded the European Transport Award for Sustainability in the category ‘Components and Aggregates’, not only addresses the challenges of the industry, but actively contributes to the avoidance of impending driving bans and delivery restrictions.

ABM supplements ePower with many customer benefits. The generators are optimized and housed compact in the axle. Through their longevity, robustness and efficiency they provide a reliable basis for sustainable and high-performance energy generation throughout the entire trailer journey.

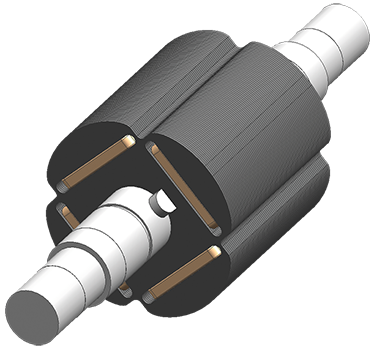

New Development: Externally Excited Motor

An externally excited motor for e-mobility, which is still under development at ABM, is also sustainable and efficient. At its booth, ABM will offer an early look at the innovation, which is completely free of rare earth magnets. The good field weakening behaviour mirrors the torque/speed requirements for traction drives, because they can be controlled more efficient and variable.

ABM supplies drive solutions for intralogistics as a single source. The customer receives a tailored, installation-optimized, highly energy-efficient solution for the given application. With this, ABM continues to pursue its goal of delivering high-quality, reliable drive solutions and as a partner supporting its customers with engineering and manufacturing expertise.

ABM’s new inverters are used in all common container and pallet conveyor applications.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

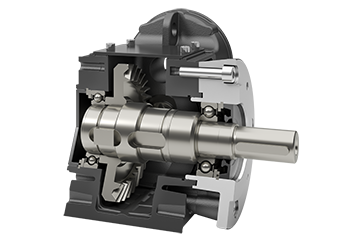

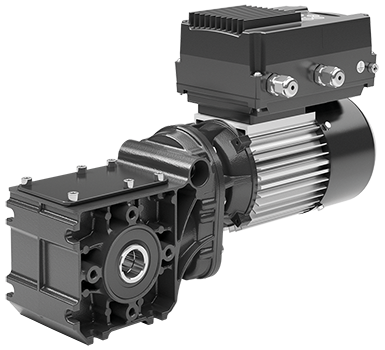

The two-stage bevel gearbox drive units in the TDB series have plug-and-play capabilities for easy integration.

As a systems supplier, ABM offers all drive systems for driving, lifting and steering forklift trucks and pallet trucks from a single source.

ABM presents highly flexible System Solutions at SPS 2023

>ABM Greiffenberger will present all-in-one drive solutions at the SPS (14 through 16 November in Nuremberg, Germany) in Hall 3a at Booth 400. With solutions precisely tailored to individual requirements, high quality is ensured. Depending on the task, the systems supplier can assemble one using standard modules, supply a solution for a specific industry or develop a tailored solution in close cooperation with the customer as partner.

As a full-service provider, ABM Greiffenberger develops and manufactures drive systems for stationary and mobile applications. These are suitable for numerous industries such as machinery / equipment manufacturing, intralogistics, electric vehicles, medical technology, energy, gases and fluids, and many other fields. The drive systems include not only induction motors – but also permanent magnet synchronous motors: With their high efficiencies, motors in this series can further improve the energy balance of the drive systems. The requirements of premium energy efficiency class IE5 are already met. The Sinochron motor features a compact design, can easily be integrated into an overall system – and offers sensorless operation. As a result, the series can apply the full torque immediately for starting from a standstill. This is a clear added value that sets it apart from other products on the market, especially in terms of availability, performance and cost.

The portfolio also includes helical, parallel shaft and angular gearboxes with various configurations, e.g. with flange, solid shaft or hollow shaft. ABM additionally offers gearboxes, combined with induction or Sinochron motors, with inverters for specific industries and applications. Inverters are optionally available with various BUS systems for enabling connectivity – ‘digitalization’ is the keyword here. The inverters can be installed centrally in the control cabinet or in decentralized positions in the field and are also available in customized versions.

The drive specialist thus has myriad combination possibilities available for a wide range of applications – to provide both perfectly fitting standard or custom solutions. To be able to do this, ABM has an intelligent modular system containing the various gearbox configurations, which the provider adapts to the respective application. The user receives a drive solution that is quickly available and offers cost efficiency in terms of functionality and power consumption for the given application.

ABM also offers industry-specific drive solutions – such as hoist drives: Parallel shaft geared drive units with additional special properties for hoisting applications such as bridge cranes.

If a special application-specific drive system is needed, ABM can also develop a completely new system solution in close cooperation with the customer as a partner. The individual solution is precisely tailored to the requirements and offers maximum added value in terms of performance and energy efficiency as well as permanently and considerably lowered costs.

ABM offers system solutions from an extensive portfolio of motors, gearboxes and controllers.

Individually tailored to conveyor applications: Geared motor and inverter are selected from a modular system.

ABM also supplies industry-specific lifting solutions consisting of geared motors and inverters.

System integration at the highest level - Specific solutions are developed for a given application, e.g. a stair lift, in close cooperation with the customer.

ABM Greiffenberger welcomes nine Trainees

>This year the ABM Greiffenberger team welcomes nine trainees. Starting on September 01, 2023, they are learning technical professions like electronic technician for machines and drive technology, mechatronic engineer, tool maker and metal cutting machine operator. With them, a total of 31 young talents complete their apprenticeship at ABM Greiffenberger. All graduates from 2022/2023 were offered permanent employment.

„We focus on targeted development of young people to meet our need of skilled trades. Our trainees receive comprehensive support and encouragement. After successful completion, we offer a wide range of prospects and career paths“, explains Thomas Heim, Managing Director of ABM Greiffenberger Antriebstechnik GmbH. As an employer, ABM Greiffenberger offers many advantages. “During the apprenticeship, we cover the costs for work clothes and textbooks, for example, and good results in the intermediate and final exams are rewarded. In addition, our trainees – like all employees can cash in on numerous benefits such as job bikes, employee discounts, a company pension scheme, holiday and Christmas bonuses and much, much more.”

Vacant Apprenticeship Positions 2023 / 2024

In order to successfully meet the challenges of filling apprenticeship positions, ABM Greiffenberger offers young people assistance in choosing a career at an early stage. Be it through meet and greet days and student internships at ABM, participation in recruiting fairs as well as presentations at schools or even an own day of training.

On the career portal www.abm-drives.com of ABM Greiffenberger, interested parties can always find all open apprenticeship positions for the year 2024 as well as information on further entry and career opportunities. You are also welcome to meet our team in person. We will be available at the following events to answer all your questions about training:

- Apprenticeship Fair in Marktredwitz (September 30, 2023)

- Apprenticeship Fair in Kemnath (October 14, 2023)

- Apprenticeship Day at ABM Greiffenberger (October 28, 2023)

From left to right:

Marc Mayer (Youth & Trainee Representative), Jan Tröger (Chairman of the Works Council), Matthias Lippert (Trainer Mechanics), Mirko Schönfelder, Bastian Scherzer, Tim Benker, Ewgenij Rykunov, Dominik Marx, Julian Linß, Fabian Hösl, Vanessa Prechtl, Julia Wunderlich, Eduard Eckenberger (Trainer Electrical Engineering), Dr. Norbert Neumann (CEO) and Bernhard Wenning (Training Manager)

All from a single source

>ABM Greiffenberger supplies complete drive solutions for intralogistics. If necessary, the systems supplier can adapt the solutions, consisting of motors, gearboxes, brakes and frequency inverters, for specific applications and customers. ABM works closely and in partnership with the customer. The solutions are used in applications including automated logistics systems with conveyors, lifting equipment and forklift trucks as well as automated guided vehicles (AGVs). The customer receives everything from a single source.

‘As a full-range provider of drive technology, we develop and manufacture tailored drive solutions for intralogistics that can be optimally integrated into the respective applications,’ explains Stephan Thoma, product manager for inverters at ABM Greiffenberger. One such solution is the highly efficient Sinochron motor. The permanently excited synchronous motor can be used, for example, without a gearbox as a direct drive in container conveyors for small loads of up to 180 kg. The motors have especially high efficiencies in the part-load operational range in which the drives in the systems are primarily operated. Typical travel speeds are 0.3 to 1.5 m/s.

‘Thanks to its special design, the series is perfect for operation with sensorless control. In addition, even the smallest IEC frame size of 63 can already reach nominal torques of 4.5 Nm. This drive solution differs from the induction motor by a short-time overload capacity that is approximately twice as high,’ reports Thoma. Because of this power density, ABM can make the motor series more compact. This is a clear advantage for the design engineer, who usually receives a smaller drive and can thus reduce the installation space and energy consumption. Via the sensorless speed control, the control system calculates the rotor speed as well as the rotor angle at a given time from the electrical feedback. With this information, the currents for torque generation can be fed precisely to the motor. As a result, even without an expensive encoder, the Sinochron motor has outstanding control characteristics over a large speed control range. Because the drive does not require any sensors, it is also more robust. This ensures maximum system availability – a clear advantage for the total cost of ownership. Depending on the application, the service life of the drives can reach 50,000 hours.

‘Our Sinochron motors are energy-efficient and can be operated over a wide temperature range,’ reports Thoma: ‘Our customers can use the series at temperatures of -30 °C to +60 °C and thus even in deep-freeze storage facilities.’

Even for Heavy Loads with added Gearbox

For extended container or pallet conveyor systems, i.e. for transporting loads of up to a tonne per load carrier, ABM combines its motors with helical, parallel shaft or angular gearboxes. Specifically for these applications, ABM has supplemented its parallel shaft gearbox series with the two compact two-stage types FG182 and FG282, offering nominal torques of 180 Nm and 280 Nm respectively. Users benefit from high permissible radial loads and universal mounting options for the parallel shaft gearboxes. Hollow and solid shafts as well as shrink discs are available. The series can be supplied with or without flange. Because the gearboxes are also light and compact, they are easy to handle during installation.

ABM Greiffenberger always focuses on customer needs. ‘We select the best drive solution in terms of functionality and efficiency from our modular system for the given application,’ says Thoma. The modular principle means that even special requirements of the system manufacturer can be met with standard components. This positively affects the quality because only proven modules are used. Various mechanical and electrical interfaces are available to simplify installation. ABM realises all connections as plug-and-play solutions. Plug-in connector systems ensure fast, error-free installation.

ABM also develops completely new system solutions. The big advantages of an individual solution are the maximum added value and the permanently and considerably lowered costs that result because these drives are precisely tailored to the requirements.

Without a Frequency Inverter, nothing works

Most applications in intralogistics are implemented with speed control. ABM Greiffenberger offers an extensive portfolio of products for this, which is rounded off with two new sizes made especially for container and pallet conveyor systems. ‘With power outputs of up to 2.2 kW, we cover all the applications needed in conveyor technology,’ reports Thoma. ‘The user profits from optimal control characteristics for both induction and Sinochron motors.’ Because the frequency inverter controls the permanently excited synchronous motor without any sensors, costs are lowered and availability is increased. The devices are designed for a service life of 30,000 hours under full load in continuous operation. The pluggable connection allows for an easy and quick installation. Users receive the new frequency inverters with a protection rating of up to IP54 and an overload capacity of 250 per cent. The frequency inverters are also suitable for use at temperatures of -30 °C to +40 °C and thus even in deep-freeze storage facilities.

Frequency Inverters with numerous Features

Plug-in connections for the power supply (daisy chain principle) and control terminals/inputs make installation fast and easy. Using the Ethernet-enabled BUS systems the inverters communicate with higher level controls.

The inverters can optionally be equipped with brake choppers and the ability to control mechanical brakes. Thoma explains: ‘With sensorless control we ensure a maximum speed control range. This feature sets us apart from our competitors.’ The result is lowered costs and higher availability. The decentralised inverters can be integrated on the drive and are also suitable for field use in the vicinity of the motors as wall-mount versions. The inverters use machine-to-machine communication to connect to higher-level controls, making predictive maintenance possible. The inverters are thermally independent and require no additional fans. ‘Through the intelligent combination of motor, gearbox and inverter from our modular system, we can control the complexity,’ says Thomas. The reduced number of drive variants represents a huge advantage for users when it comes to storage, service etc.

As a systems supplier, ABM can offer drive solutions for most applications in warehouse logistics – from small roller conveyors to pallet conveyors. ‘The user receives everything from a single source,’ says Thoma.

ABM’s new inverters with power outputs of up to 2.2 kW are used in all common container and pallet conveyor applications.

An accumulation roller conveyor with a Sinochron motor as a direct drive – controlled with an ABM inverter.

Container conveyor technology: a belt conveyor with an angular gearbox including an ABM inverter as a drive.

Chain conveyor for pallet transport: ABM’s parallel shaft geared drive unit combined with the ABM inverter is ideal for heavy loads.

Compact Platform with the Highest Level of Integration

>Electric drives in conveyor systems, lifting equipment and forklifts are the motors that drive modern, efficient and reliable intralogistics. ABM Greiffenberger develops and manufactures platform-based systems for stationary and mobile applications. The drive solutions consisting of motors, gearboxes, brakes and frequency inverters tailored to specific applications are developed by the specialists at ABM Greiffenberger in close partnership with their customers.

‘Traction, lifting and steering in forklift trucks, for example, require both know-how and the right drive components,’ says Mayk Krüger, Senior Manager of Material Handling at ABM Greiffenberger. ‘Our solutions consistently comply with strict environmental requirements, are particularly safe and enable precise movements even at low speeds thanks to their high responsiveness.’

ABM supplies all drive components, including motors, gearboxes, sensors and inverters, from a single source. And that’s not all: The drive specialist develops and manufactures complete gearbox–motor drive units in-house – this system expertise sets the company apart from the competition. With the modular system, ABM is always able to supply the right solution – irrespective of the vehicle type.

‘Our drives make dynamic movement and precise manoeuvring of industrial trucks possible for users, even in tight spots,’ Krüger says. ‘Also, our solution provides forklift trucks with excellent climbing performance.’ The TDB series can easily be integrated into a given application via plug and play. The two-stage bevel-helical gearbox drive unit offers high performance and low energy consumption. It can be used for both manual and electric industrial trucks. It is characterised by high-power density and outstanding efficiency. Combined with a steering drive and equipped with a fully integrated and reliable sensor monitoring system, it gives the user a fully integrated traction and steering drive solution. ‘Through the vertical design, the small envelope size and the numerous series options, this gearbox drive unit is ideal for a multitude of applications – for example, in reach trucks, tow tractors, automated transport systems and sweeper/scrubbers,’ says Krüger, describing the extensive applications for the drives. Users can work reliably for lengthy periods, even with smaller batteries.

Various steering options

ABM Greiffenberger offers the bevel gearbox drive units for wheel diameters of 230 and 254 mm based on power output, speed and load capacity: Gearbox ratios and motor performances can be tailored precisely to given applications. The compact TDB series offers drive torques of up to 750 Nm. ‘It can be equipped with various steering options,’ says Krüger. The manual steering system, for example, is suitable for direct mounting on the drawbar. The user receives a space-saving, robust and accordingly long-lasting solution. An electric power steering system can be realised with external steering via spur gear. If necessary, ABM can supply a zero position sensor for the steering position as well as an absolute encoder for steering right on the traction gearbox. A third possibility is an integrated electric steering drive. The user profits from redundant steering monitoring, maximum ride comfort and a high level of safety.

For the traction area, ABM offers temperature monitoring via temperature sensor. Speed recording is done via an incremental encoder with up to 64 pulses per revolution. All AC traction motors offer energy recuperation via regenerative braking to save energy. An electromechanical holding brake is integrated for parking and emergency stopping. Krüger says: ‘With this diversity of functionalities and possible combinations, we support both developers of individual applications and OEM project managers of cross-fleet platforms with suitable drives.’

Systems Supplier with high Level of Development Expertise

ABM Greiffenberger scores points both with its extensive know-how and experience in the development of application- and customer-specific drives and with its platform concept, which ensures that customers quickly receive cost-optimised solutions. ‘However, we can also specifically address customer requirements,’ says Krüger. ‘Thus, we are not a standard supplier and offer our customers a measurable added value.’

ABM supplies all products, including motors and gearboxes as well as suitable electronics, from a single source.

As a system supplier, ABM Greiffenberger offers all drive components for forklift truck traction, lifting and steering from a single source.

Manual or electric steering versions are available. A fully integrated drive unit can be supplied and consists of electric steering and redundant steer motion monitoring directly on the drive wheel.

Bevel Gear Drives TDB 230 with integrated electric steering: Highest integration and impressive driving comfort and safety.

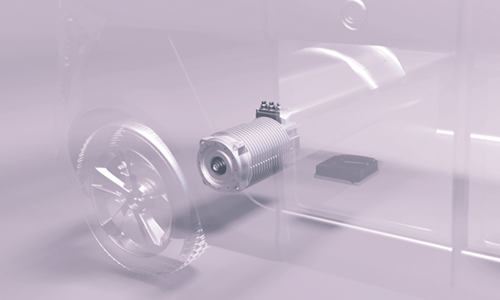

Motors for High Load Peaks and Continuous Performance

>Electric drives in conveyor systems, lifting equipment and forklifts are the motors that drive modern, efficient and reliable intralogistics. ABM Greiffenberger develops and manufactures platform-based systems for stationary and mobile applications. The adaptable drive solutions consist of motors, gearboxes, brakes and controllers and are developed by the specialist in close partnership with customers.

Drives for electric vehicles must meet high expectations: They have to be environmentally friendly, efficient, powerful and inexpensive to maintain. “ABM Greiffenberger already started to transfer its know-how from battery-powered drives to E-mobility before the turn of the millennium and even back then was already able to implement the first projects,’ reports Mayk Krüger, Senior Manager of Material Handling. Users benefit from the full-service provider’s decades of expertise: They receive powerful drives with high efficiencies.

Compared with standard motors, the ABM drives are much more compact – and also extremely robust, durable and maintenance-free in harsh operating conditions. ABM offers a platform concept with manifold options – customers receive cost-optimised, easy-to-integrate system solutions. The drive specialist also adapts the motors to individual customer requirements and applications.

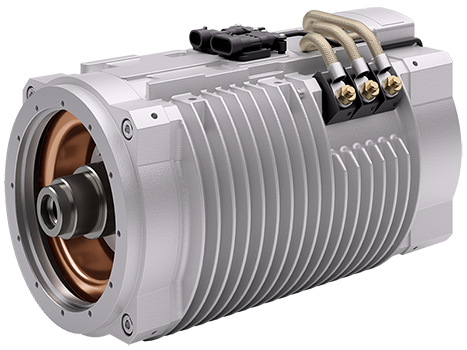

ABM Greiffenberger offers motors for auxiliary units in trucks and buses as well as traction drives for use in a wide variety of electric vehicles. Krüger says: ‘For our AC drives with housings, we have optimised the cooling for longer periods of continuous performance.’ Because the drive is installed on the differential axle at a right angle to the direction of travel, the developers have adapted the ring ribs of the drive appropriately to ensure optimal air cooling. This makes these motors suitable for journeys with high load peaks and high continuous performance. Even in harsh or dirty environments, reliable operation of the on- and off-road vehicles is ensured. Depending on the motor size, peak powers of 20, 50 and 90 kW and torques of 45, 130 and 260 Nm are achieved.

Sensors monitor the motor temperature and record the speed. Speed and torque control is provided via an external AC controller. Upon request, ABM can deliver a parameterised controller as a plug-and-play solution tailored to the application and can also optionally install an electromechanical holding brake. Versions with IP 66 protection rating and UL certification can also be provided.

The drives can be used in all E-mobility applications, including utility vehicles, golf carts and agricultural machinery as well as electric trucks and on- and off-road vehicles. Traction motors for electric vehicles such as baggage tow tractors and airport ground support equipment (GSE) vehicles are additional applications.

ABM offers a platform concept with multiple options.

ABM housing motors for battery-powered vehicles ensure due to the ring-shaped design of the ribs an optimized heat dissipation.

Drive Technology for Intralogistics Applications with a Distinct Added Value

>ABM Greiffenberger will present complete drive solutions at the LogiMAT (25–27 April) in Hall 3 at Booth 3B15. In close cooperation with customers, the systems supplier tailors each solution to the customer’s application and requirements. The provider’s focus in Stuttgart will be on system solutions for intralogistics along with digitalisation and thus the company’s new inverters, amongst other things.

Drive Technology for Conveying Technology

The high-efficiency, dynamic motors in the Sinochron series are one such drive solution. Without gearboxes, they can be used as direct drives for small loads – in roller conveyors for loads of up to 180 kilograms. Owing to their special design, the permanently excited synchronous motors are perfect for operation with sensorless control. Their high power density means that ABM can make the Sinochron series extremely compact. The user can then often select a smaller motor that requires less installation space and consumes less energy. The Sinochron series offers a high system availability – an important advantage for the total cost of ownership. The drives also have a service life of up to 50,000 hours. Their properties make them suitable for applications such as roller conveyors that need to transport containers of different weights, often over distances of several kilometres.

For heavy loads – for example, for extended container conveyor systems or pallet conveyor systems – the Sinochron motors can be combined with gearboxes from ABM. Various gearbox drive unit designs including right angle, straight shaft helical and parallel shaft helical are available. With the special parallel shaft helical gearbox drive unit types FG182 and FG282 for container and pallet conveyor systems, users benefit from extremely reliable radial loads and universal mounting options. In addition, the low weight and compact dimensions make installation easier to handle.

ABM Greiffenberger will also showcase its inverter series designed especially for intralogistics applications in Stuttgart. This series is available in three sizes with power outputs of up to 2.2 kW. With the series, ABM covers all common applications in container and pallet conveyor systems. Installation is quick and easy via plug-in connections. The inverters communicate with higher-level controls using the Ethernet-enabled bus systems. At 250 per cent, the overload capacity of the frequency inverters is extremely high. The decentralised solutions lend themselves well to field applications near the motors. Motor mounting and wall mounting are possible. ABM Greiffenberger’s solutions thus cover the entire range of applications in warehouse logistics – from small roller conveyors to heavy-duty pallet conveyor systems.

System solutions for Mobile Drive Technology

As a systems supplier, ABM Greiffenberger offers all drive solutions for driving, lifting and steering forklift trucks from a single source. The motors, gearboxes and controllers comply with strict environmental requirements, are particularly safe and are extremely responsive for executing precise movements even at low speeds. These drive solutions include the two-stage bevel gearbox drive units in the TDB series. The drives come with plug-and-play capability for easy integration and are both powerful and energy-efficient. They offer high power densities and optimal efficiencies. The compact bevel gearbox drive units are available with manual or individual steering and with integrated electric steering drives. This is rounded off with redundant sensor monitoring. Altogether, this provides a fully integrated system solution to the user.

The drive specialist’s electric-steering hub-wheel drive units with controllers for automated guided vehicles (AGVs) or for forklift trucks will also be on display at LogiMAT. These extremely slim drive units are ideal for use in narrow vehicles. Electromagnetic service and parking brakes ensure maximum safety in operation. Specific sensors that record speed, rotor position and winding temperature can be used with the motor control system.

ABM will also show its compact, robust housed motors for electromobility applications in Stuttgart. The optimally cooled motors can be operated continuously for longer periods in battery-electric vehicles in harsh environments. Users have a motor platform with manifold options available to them and profit from cost-optimised system solutions that enable them to use fewer drive variants.

ABM’s new inverters with power outputs of up to 2.2 kW are used in all common container and pallet conveyor applications.

As a systems supplier, ABM Greiffenberger offers all drive systems for driving, lifting and steering forklift trucks and pallet trucks from a single source.

A modular building kit for mobile applications enables diverse and flexible drive configurations.

Housed motors for battery-electric vehicles from ABM feature optimised cooling in harsh environments.

System Solutions from a Single Source

>ABM Greiffenberger application-specific system solutions at SPS (8/11 to 10/11 in Nuremberg) at booth 3A-400 / hall 3A. The full-service provider for drive technology supplies motors, drives, brakes and electronics from a single source. The drive specialist works closely with its customers. User benefit from the high development and system expertise as well as the extensive know-how of the company. In Nuremberg the focus is on the increasing digitization, among other things.

The EuP Regulation (Energy using Products) of the European Parliament for single-phase induction motors comes into force on July 01 / 2023. Then the energy efficiency class IE2 will be mandatory for two, four, six and eight pole continuously operated single-phase induction motors with a power higher than 0.12 kW. ABM Greiffenberger already supplies energy efficient three-phase induction motors. With built-in electronics these can also be operated in the future on widely used 230V single-phase mains at any time. A single-phase motor with capacitors is no longer required. All advantages of the three-phase motors such as a higher starting torque, lower starting current as well as a lower grid load can also be used on single-phase mains. Moreover, in comparison with the single-phase version the three-phase induction motor with built-in electronics excel with compact design, higher power density and efficiency as well as an optimised quiet running.

In combination with the built-in electronics the single-phase induction motor is controlled fully electronically. A capacitor is no longer needed. This makes the drive system significantly more durable with low maintenance. Optionally, a temperature monitoring of the motor and the power section of the electronics is available.

Expansion of the Parallel Shaft Geared Drive Units by compact, two-stage Types

The system provider has expanded the existing parallel shaft gearboxes (FG series) and presents the FG182 and 282 types in Nuremberg specially for the conveyor and pallet conveyor technology in intralogistics. The extremely compact two-stage solutions offer nominal torque of 180 and 280 Nm and thanks to their gear ratio and compactness they can also be used as travel drives in lifting applications. The user also benefits from highly reliable radial loads as well as the universal mounting options such as hollow and solid shaft, shrink disc, version with and without flange. Furthermore, the low weight and the compact design enable easy handling.

New Frequency Inverter of up to 2.2 kW for Intralogistics

Applications in intralogistics are primarily controlled with frequency inverter. The inverter series for the conveyor and pallet technology is completed with two more frame sizes specially developed for this industry. Thanks to the power range of up to 2.2 kW higher loads can also be moved. Thus, ABM Greiffenberger covers all required applications.

The user benefits from the optimal control properties both with asynchronous as well as with Sinochron motors. The frequency inverter can operate the permanently excited synchronous motor without the use of sensors. This lowers the costs and increases availability.

The inverter are designed for a service life of 30,000 hours under full load and continuous operation. Pluggable connections allow an easy and quick installation. The inverters communicate with higher-level control systems via Ethernet-capable BUS systems.

With a protection class of up to IP54 and a high overload capacity of 250 percent, the frequency inverters are perfect for accelerating heavy loads. They are also suitable for use at temperatures of 30 to +40° Celsius and therefore for use in deep-freeze storage.

Systems Supplier: One single Partner for your Drive Units

As a system supplier, ABM Greiffenberger develops and manufactures application-specific and installation-optimised solutions from a predefined modular system that are perfectly tailored to the application. The specialist thus continues to pursue its goal of not only supplying high-quality and reliable drive solutions, but also supporting its customers as a development partner with engineering and manufacturing expertise. Customers receive cost-efficient complete solutions with measurable benefits.

The compact, energy-efficient three-phase asynchronous motors with single-phase fed electronics offer all the advantages of a three-phase motor when operated on a single-phase mains supply.

ABM has added two-stage compact types - FG182 and FG 282 - to its existing range of parallel shaft gear units.

Two additional frequency inverters developed specifically for intralogistics applications complete the series for conveyor and pallet technology.

The First Step into the Professional World.

>On September 1, 2022, a new phase of life began for twelve young people: they started their commercial or technical apprenticeship or dual studies at ABM Greiffenberger Antriebstechnik GmbH. With them, the number of our junior staff grows to a total of 35 trainees.

"The quality of training at ABM Greiffenberger is at a high level - this is confirmed by the recurring very good final examination performance", reports Ralph Treude, CEO of ABM Greiffenberger. "With a guaranteed job offer in one of our specialist departments, we offer all trainees a long-term perspective, which is also flanked by targeted advanced training and qualification measures."

In addition to their technical skills, the young employees are encouraged to work independently. They are their own boss when it comes to realizing their particular projects; at the same time, creativity and team spirit are also required. "Our trainees have already created, planned and realized great things. For example, they designed and built a basketball machine, an air hockey game and even a candy sorting machine," says Treude.

Apprenticeship Day at ABM Greiffenberger

We cordially invite everyone who wants to find out more about our apprenticeships and gain an insight into our apprenticeship workshop to the "Apprenticeship Day". This will take place on Saturday, October 29, 2022, at ABM Greiffenberger in Marktredwitz. Various hands-on stations and interesting discussions with our trainees and trainers await the visitors. Registrations is not required.

Apprenticeship Fairs

Our team will also be happy to answer any questions you may have at the following apprenticeship fairs:

- Apprenticeship fair in Marktredwitz (September 24, 2022)

- Apprenticeship fair in Kemnath (October 08, 2022)

Applications for the 2023 Apprenticeship

Applications for the year 2023 are already being accepted. And it's very easy: Go to www.abm-antriebe.de/karriere/stellenangebote select the desired apprenticeship, enter your data, upload your report card and CV and you're done!

From left to right:

Marc Mayer (Youth & Trainee Representative), Reimund Lork (Staff Manager), Sven Fronhöfer, Bernhard Wenning (Training Manager), Emine Akkaya, Nico Pollak, Kathrin Weiß, Baki Toy, Tim Grosser, Luca Pollak, Felix Schmelber, Willi Heinl, Niklas Schindler, Markus Nickl, Ralph Treude (CEO), Jan Tröger (Chairman of the Works Council) and Marco Meier (Vice Chairman of the Works Council) .

(Not on the picture Leon Wieland)

Drive Solutions for Mobile Applications in Material Handling

>The electrification trend is just taking off in mobile applications for material handling. Electric drives are dynamic, efficient, powerful and above all reliable. They are thus suitable for forklifts, automated guided vehicles (AGVs) and pallet trucks. ABM Greiffenberger supplies the appropriate motors, gearboxes and electronics developed and manufactured in-house – and adapted to the individual application. This makes the drive specialist from Marktredwitz a valuable partner for customers with diverse intralogistics applications.

Many things are moved in and around a logistics centre – and wherever this happens, drives are required. It starts with employees coming to work in electric buses. Lorries transport goods to the receiving point – drives for auxiliary units such as hydraulic pumps, compressors and fans are needed here. When the lorries drive up to the dock, rolling doors open and close so that the employees can load or unload. By means of pallet trucks, forklifts or AGVs, the goods are moved to pallet and accumulation roller conveyors, which bring them to the high-bay storage area. Ergonomic lift assists are used for goods handling and machines are used for cleaning the production floors. ‘We supply suitable motors, gearboxes, brakes and inverters for all these applications – from a single source,’ says Michael Lühmann, Head of Sales & Marketing at ABM Greiffenberger. ‘This makes us a systems supplier for the entire intralogistics field.’

The drive specialist offers ready-to-install plug-and-play systems available as modules within a platform concept for the mobile sector. ‘We can thus easily combine gear ratio and motor size with brakes and sensors and in this way optimise customer applications. The finished solutions can be integrated into the different vehicle types,’ reports Lühmann. This is by no means always the case on the market.

ABM Greiffenberger can completely cover the functions of traction, lifting and steering with its solutions in the mobile sector. They comply with strict environmental and emission requirements, are particularly safe and are extremely responsive for precise movements even at low speeds. ‘With this we are responding to a growing market. Because electrification is advancing more and more in mobile applications in intralogistics,’ says Michael Lühmann. Electric drive systems are more sustainable and more efficient. They run reliably and smoothly, are dynamic and durable, and offer safety. For that reason it is only logical for electric drives to be increasingly employed in a number of applications.

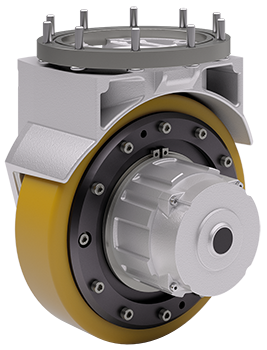

Hub wheel drives with electric steering

The drive specialist offers three gearbox types for mobile applications – including the robust TDH series hub wheel drives. This type of drive is extremely compact because the drive components are integrated into the drive wheel. The user profits from high static and dynamic wheel loads. Thanks to high wheel torques at low speeds, the user can precisely manoeuvre and drive up inclines with, for example, pallet jacks, aerial work platforms, AGVs or sweeper/scrubbers. ‘We also offer the hub wheel drive with electric steering,’ says Dipl. Ing. Mayk Krüger, Head of Mobile Drive Technology. With its low installation height, this version is ideal for forklifts and automated guided vehicles. The user benefits with the hub wheel drive with electric steering from a precisely controllable and efficient AC motor technology. It brings a torque of up to 300 Nm to the wheel and has a drive torque of 360 Nm. The redundant steering sensors provide for precise steering. Moreover, the drive is durable, maintenance-free and highly loadable.

Bevel Gearbox Drive Units: Innovative platform concept

With the bevel gearbox drive units in the TDB series for wheel diameters of 230 to 254 mm, the systems supplier has efficient components featuring high performance and low energy consumption in its portfolio. The ready-to-install systems are modularly designed and are available as a platform concept. The complete solution comprising the motor, gearbox and sensors can easily be integrated into different vehicle types. In industrial trucks the TDB series bevel gearbox drive units provide high climbing performance and acceleration. They offer responsive and dynamic steering over the entire speed range.

The bevel gearbox drive unit is available in three versions – for example, with an integrated steering drive. The traction motor is vertically mounted in the fixed version. The operator profits from, amongst other things, redundant steering monitoring, maximum integration and excellent ride comfort with high safety.

ABM Greiffenberger also supplies the bevel gearbox drive unit for manual steering. The vertical mount of the traction motor in the rotating version is designed for direct drawbar mounting. This robust and durable solution features space-saving installation.

‘Application-specific steering is also possible; customers can also combine the TDB bevel gearbox drive units with their own steering drives,’ says Mayk Krüger. They are thus suitable for electric power steering systems and can be controlled via spur gear. A zero position sensor can optionally be attached for calibration of the steering positions.

Speed recording in this series is done via an incremental encoder with up to 64 pulses per revolution. There is also an option to use the AC technology with regeneration capability. An electromechanical holding brake is integrated for parking and emergency stopping.

Parallel shaft gears: Quiet and efficient

The TDF series helical gearbox drive units offer an especially high efficiency, low wear and quiet running even at high loads. ‘We achieve this via the high-contact-ratio helical gear technology,’ explains Lühmann. The gearboxes are suitable for use in pallet jacks and three-wheel forklifts, for example. ABM manufactures the gearboxes from die-cast aluminium. Thus customer-oriented solutions can be provided at a good price-to-performance ratio. The design and the matching of the material to the application make sizes 200 mm and 230 mm light and stable. Speed recording is done via an incremental encoder with up to 64 pulses per revolution.

Systems supplier with high level of development expertise

ABM Greiffenberger scores points both with its extensive know-how and experience in the development of application- and customer-specific drives and with its platform concept, which ensures that customers quickly receive cost-optimised solutions. ‘However, we can also specifically address customer requirements,’ says Krüger. ‘Thus we are not a standard supplier and offer our customers a measurable added value.’

One example of an individual development is an electric differential axle for forklift trucks and transport systems. Precisely adapted to the application, the differential axle has optimised interfaces and can thus easily be implemented into the vehicle.

ABM supplies all products, including motors and gearboxes as well as suitable electronics, from a single source. Even complex prototypes can be produced at short notice with additive manufacturing.

‘Our drives offer high performance and system availability,’ stresses Lühmann. This is especially important in material handling because the vehicles are often used in two- or three-shift operations. Reliability is extremely relevant here. Operators therefore rely on drives that are maintenance-free, robust and durable. ‘We consistently pursue our goal of not only delivering high-quality drive solutions, but also supporting our customers in the capacity of a partner with engineering and manufacturing expertise,’ says Michael Lühmann.

The platform concept of the TDB bevel gearbox drive units offers users numerous options:

Depending on the application case, integrated, manual or application-specific steering can be selected.

Plug-and-play for automated guided vehicles – the efficient TDH230i hub wheel drive with electric steering enables precise and safe manoeuvring.

Electric differential axle for forklift trucks and transport systems – an individual drive system specially adapted to the specific application.

ABM Greiffenberger 如何驱动内部物流世界

>ABM Greiffenberger为物流中心的所有移动和固定应用提供合适的驱动。通过与客户的密切合作,一站式内部物流提供商提供优化的模块化和定制化系统解决方案,为用户提供最大的附加值。 参观者可以在斯图加特展会3号展厅B15展位找到相关强大驱动的信息。

许多物品都需要搬入物流中心及其周围 - 无论这种情况发生在哪里,都需要驱动减速机。它始于移动应用程序,例如:将员工运送到工作地点的电动公交车或将货物运送到接收点的卡车 - 这里需要液压泵,压缩机和风扇等辅助单元的驱动。当卡车驶上码头时,卷帘门打开和关闭,以便员工可以装卸货物。通过托盘搬运车、叉车或自动导引车 (AGV),货物被搬运到集装箱和托盘输送设备上,从而将它们带到高架存储区。还布置了其他设备和机械设备,例如,用于处理货物的符合人体工程学的升降机辅助装置和用于清洁建筑物地板的机械设备。ABM Greiffenberger为所有这些应用提供合适的电机、齿轮箱、制动器和变频器 - 用于工业用电或电池供电。

这些驱动解决方案包括 Sinochron 电机系列,参观者可以在展会我们的展位上了解该系列。永磁同步电机采用特殊设计,非常适合无传感器控制操作。同步电机的优点是高功率密度和紧凑的尺寸。这些电机的效率超过90%,在内部物流应用中得分,在这些应用中,驱动仅在部分负载下运行,以及在卡车和公共汽车的辅助单元中运行。

ABM Greiffenberger在其高效的驱动技术产品中增加了紧凑而强大的液冷电机。电机具有较高的热稳定性,并提供出色的防护保护,高达IP6K9K。它们可以通过变频器进行控制,并且可以轻松的连接到所有ABM同轴,平行轴和直角轴齿轮箱上。它们是移动驱动技术等领域的理想选择,例如,它们被用作电动汽车和建筑机械中的集料和牵引驱动。

降低复杂性

ABM提供合适的变频器,可与所有应用的相应驱动系统最佳匹配。它们满足可控性、网络化、数字化和连接技术以及其他要求。

用于AGV的轮毂驱动 - 现在还可配备电动转向

ABM将展示另一项创新,即用于AGV和叉车的带电动转向的轮毂驱动。它的驱动扭矩为360 Nm; 集成的电动转向系统为车轮带来高达 300 Nm 的扭矩。用户受益于精确可控和高效的交流电机技术。用户可从单一来源获得完整的解决方案,并且只需关注驱动技术的接口。

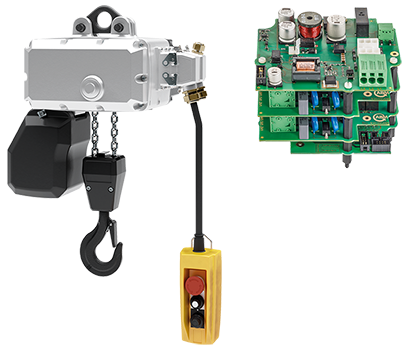

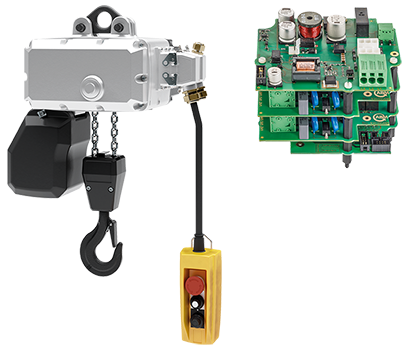

集成电子控制的环链葫芦

强大的环链葫芦也将在LogiMAT上展出。它们采用模块化设计,通过摩擦联轴器提供可靠的过载保护。全新的电子控制装置集成,通过即插即用技术,操作人员可以轻松扩展基本版本以包括运行功能。ABM Greiffenberger的新解决方案特别耐用 - 开关触点不会磨损。耐腐蚀且坚固耐用的环链葫芦还可以在恶劣环境中可靠地运行。高质量的斜齿轮传动装置可实现静音运行并降低噪音排放。

系统化供应商:内部物流的一个合作伙伴

ABM Greiffenberger 是内部物流中所有应用的系统化供应商,并开发针对相应应用进行最佳定制、安装优化的解决方案。因此,ABM保持了其提供高质量,可靠的驱动解决方案的目标,并以具有工程和制造专业知识合作伙伴的身份为客户提供支持。

![]()

同步电机的优点是高功率密度和紧凑的尺寸,效率可达90%或更高

展会产品还将包括可靠和节能的环链葫芦,并集成电子控制

高效的 TDH 230 轮毂驱动现在也可配备电动转向系统

瑞士KYBURZ股份有限公司的电动汽车信赖ABM格莱芬伯格驱动技术

>KYBURZ瑞士股份有限公司在瑞士苏黎世附近的弗雷恩斯坦办事处,是高质量移动和运输车辆解决方案的国际领导者,例如: 用于邮政运营商投递信件和包裹。在驱动技术方面,依靠ABM格莱芬伯格的全面支持,从概念到系列化生产,ABM从单一来源提供一切可能性。

Martin Kyburz先生于1991年创立了瑞士KYBURZ股份有限公司。如今,公司已拥有 150 名员工,是城市货物运输车辆的主要制造商之一,得益于自动停车制动器和倒车功能,即使在寒冷条件下,这些车辆也能够安全、快速地到达目的地。这包括 KYBURZ DXP车型,这款电动车辆将两轮车的效率与三轮车的安全性和稳定性相结合。德国、芬兰或奥地利等多个国家的邮政运营商以及温特图尔或蒙特勒等众多城市都在使用 DXP车型。然而,邮政和物流公司并不是唯一依靠这种环保汽车的公司,休闲功能的电动跑车也非常受欢迎,确保了无线的驾驶乐趣。这就是为什么瑞士开发了eRod车型,一种被批准上路行驶的电动赛车。

KYBURZ的研发主管Daniel Weber说: “我们提供全面的服务,我们开发、生产汽车,并注重售后服务。我们还会在使用后将它们回收、加工或处理它们。”目前,全球有超过2.3万辆这种电动汽车在行驶。除了美国,公司还活跃在世界各地的市场。

要求: 高性能和高效的驱动

用户有很高的期望。特别是邮政服务,必须迅速和可靠地运送货物,需要高效、环保、可靠和廉价的车辆来维护。这对驱动提出了特别高的要求,因为邮递员必须能够驾驶满载的车辆在陡峭的街道上行驶,并且能够随时加速。由于这些车辆每天都在使用,加速度和距离都起着重要作用,这就要求电机的性能和效率。

2011年10月,KYBURZ瑞士股份有限公司向ABM 格莱芬伯格寻求平衡。作为一家全方位服务提供商,在上弗兰科尼亚的马克特雷德维茨的驱动专家们开发和制造固定和移动应用系统,这些系统安装在传送带、起重葫芦或叉车物流中。除了模块化系统解决方案外,ABM还通过客户和特定应用的驱动解决方案来确保客户可衡量的附加值, ABM与客户密切合作。" 甚至在千禧年之前,我们就已经开始将我们的技术从电池驱动的应用转移到电动汽车上。甚至在那时,我们就能够实施第一个客户特定项目。”ABM移动车辆技术的研发主管Jürgen Schliermann 说。“我们很早就认识到了新趋势——这很重要,特别是在电动汽车这样面向未来的行业。由于我们全面的开发和生产能力,我们考虑到了这一点。”

良好的启动加速性能

KYBURZ的Daniel Weber解释说: “我们一直在为不断增长的产量和用户需求寻找一个可靠的合作伙伴。”“我们熟悉ABM的高水平专业知识和供应商的良好声誉。”驱动专家为DXP车型提供端盖式交流电机。这些强大的三相异步电动机仅重约22公斤,噪音小,环境友好,并为有压力的启停操作而优化。他们的高加速能力给人留下深刻的印象,即使从静止的位置,电机也正适合这些应用操作。ABM专家Schliermann解释说:“重量优化的端盖式交流电机也很坚固耐用,由于其特殊的设计,无需外壳,适合于高峰值载荷和高动态的应用。”发热的产生是大扭矩和低速的一个主要问题,这种挑战可以通过ABM驱动器来解决。

对于KYBURZ来说,拥有一个很少或不需要维护的驱动也很重要。此外,电机从免维护的磷酸铁锂电池中获取能量,外部驱动控制器承担电源和速度/扭矩控制。由于与控制器的相互优化,整个系统被很好地调节,确保高水平的功率密度。Schliermann表示: “我们可以提供一款轻便、高效、紧凑的驱动,可以优化加速,提供良好的驾驶动力,因此也可以实现长续航里程。”

激情代替排放

由于良好的合作和可靠的产品,ABM驱动也安装在eRod车型。该车重600公斤,最高时速可达120公里,行驶里程约180公里。由于强大的电驱动,跑车为充满激情的驾驶者提供了最大程度的驾驶乐趣。Jürgen Schliermann报道说: “我们已经开发了环形散热筋电机,只需要调整它的电气性能。”与端盖式交流电机相比,紧凑且只有43公斤的交流驱动有一个外壳。还有散热筋的径向结构。既保护驱动免受灰尘,又能确保良好的散热。它与驱动方向轴向安装在差速器轴上。Schliermann解释说:“多亏了这个安装位置,我们调整了驱动的散热筋布置,确保了最佳的空气冷却。”这种解决方案适用于高峰值负荷和高连续性能的行程”。

全面受益

“通过ABM驱动解决方案,我们在所有应用中都实现了最优的解决方案价值。”Weber高兴地提到。“这还包括更高的耐高温性能,得益于此,我们的车辆可以在性能极限下行驶更长时间。”KYBURZ对两种驱动解决方案都非常满意: 因为邮政车辆每天都在使用,而eRod通常只是偶尔使用: ABM驱动适用于短、动态的延伸以及邮政服务中的连续行驶。

从这个项目中发展出了一种合作关系。“我们总是能得到快速、有力的支持。如果需要修改,我们总能迅速找到合适的解决方案”,Weber描述道。“正是由于这种合作伙伴关系,我们总是能找到一个完美的系统解决方案。得益于我们在这种驱动技术方面的丰富经验,我们的研发成本通常控制在一定范围内。

ABM选择了DXP系列的可持续运输车型,因为它的能效和零排放。“我们使用车辆往返于上弗兰科尼亚的马克特雷德维茨的两家工厂之间,我们的员工也很兴奋。” Schliermann很高兴的说。

免维护的交流驱动适用于高负载峰值和高连续性能的里程

图: ABM 格莱芬伯格驱动技术有限公司

通过将驱动轴向安装到驱动方向,进一步支持已经优化的空气冷却,也请关注我们的视频。

图: ABM 格莱芬伯格驱动技术有限公司

零排放eRod提供最大的驾驶乐趣,无论是在道路上行驶还是越野。

图: KYBURZ瑞士股份有限公司

研究生工程师(应用科学大学)Jürgen Schliermann, ABM格莱芬伯格移动车辆驱动技术研发部主管

图: ABM 格莱芬伯格驱动技术有限公司

Daniel Weber, KYBURZ瑞士股份有限公司研发部主管

图: KYBURZ瑞士股份有限公司

Thank you for 470 years of commitment

>Just like every year, the ABM Jubilee honours took place on 02 December. For ABM, the retention of employees and the creation of secure, long-term jobs are in the foreground. We are all the more pleased that we were able to thank 12 loyal employees this year. We congratulated them on 25 years (2 Employees), 40 years (6 Employees) and 45 years (4 Employees) - together an incredible 470 years - and look forward together to further cooperation as well. In small groups, the management, Robert Lackermeier and Ralph Treude, with the chairman of the works council Jan Tröger took over the honoring.

We would also like to take this opportunity to thank all those celebrating their jubilee for their loyalty and many years of exemplary service to our company: "The strong position of ABM today is the result of your expertise, loyalty, passion and experience. We are proud and grateful for your outstanding contribution to our team."

Robert Lackermeier (CEO), Ilona Kraus (45 years), Ralph Treude (CEO), Rainer Bayer (40 years), Klaus Schmelzer (45 years),

Jan Tröger (Chairman of the Works Council) and Klaus Biedermann (40 years)

Robert Lackermeier (CEO), Peter Hess (40 years), Ralph Treude (CEO), Willibald Fachtan (40 years), Gerhard Bartl (45 years),

Jan Tröger (Chairman of the Works Council) and Sebastian Neumann (25 years)

Robert Lackermeier (CEO), Simon Weiß (25 years), Ralph Treude (CEO), Andreas Kern (40 years), Jan

Tröger (Chairman of the Works Council) and Roland Kindl (40 years)

Our New Tinkerers, Doers And Planners Are Here!

>On 1st September 2021, nine apprentices started into their future at ABM Greiffenberger. The leading international system supplier for drive solutions is currently employing 31 apprentices in total in the most different job profiles.

“Already during the vocational training, many ABM benefits are waiting for you”, emphasized Dipl.-Ing. Robert Lackermeier, CEO of ABM, while he welcomed the new apprentices.

„As an enterprise of the metal and electrical industry in Bavaria, we offer benefits like, for example, a voluntary company pension, holiday pay and Christmas bonus. Moreover, we support you with all the vocational school trips outside Marktredwitz by taking over the train travel costs.”

After the vocational training, ABM Greiffenberger offers a secure and long-term perspective. The employees are supported by specific further training schemes and individual programs of the ABM Academy.

For the coming year 2022, 10 new apprenticeship places are planned. Interested parties can already now contact us. You can find all the information concerning the job profiles on our website: https://www.abm-antriebe.de/en/careers/pupils.

Open house day 2021

Provided the Corona situation allows it, the “2nd Day of Apprenticeship” will take place on 30th October 2021. Pupils, parents and teachers can visualize our company for themselves. Different presentations and participation stations as well as interesting conversations are waiting for them.

From left to right:

First row: Lea Löffler, Kaan Keles, Benno Bauer, Lukas Ullmann, Jannick Lang

Middle row: Anna Hager, Moritz Köstler, Niklas Müller, Mert Emre Özdemir, Ralph Treude (CFO), Jan Tröger (Chairman of the Works Council)

Back row: Bernhard Wenning (Training Manager), Marc Mayer, Johanna Kick (both Youth & Trainee Representative), Reimund Lork (Staff Manager), Robert Lackermeier (CEO)

瞬间从0 到 100

>作为系统供应商,ABM为固定和移动式内部物流应用开发和制造驱动系统。根据客户的要求,可以提供独立的解决方案,并降低成本,可与传送带系统实现迅速加速,甚至重载启动。这是由于ABM与客户的密切合作和伙伴关系,但定制化系统解决方案有什么特点呢?

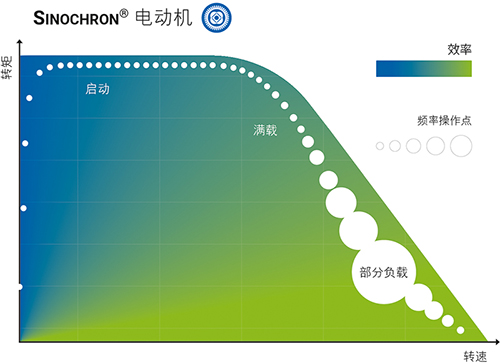

内部物流解决方案制造商对驱动器有什么要求? ABM马克特雷德维茨的研发主管Ralf Fickentscher思考了一会儿说:“客户想要高效的解决方案,使用寿命长,运行没有任何问题”。ABM是一家一站式的驱动器解决方案供应商,帮助客户节约成本,从而从快速的投资回报中获利。Fickentscher的同事、ABM团队负责人兼变频器产品经理Stephan Thoma说:“我们的电机非常高效,特别是在系统主要运行的部分负载操作范围内。”电动机能在部分负载范围内精确高效地运行,是电动机具有较高能效的主要原因之一。例如,SINOCHRON® 电机也可以在没有传感器的情况下运行,并且具有很高的启动扭矩,这在物流内部应用中尤其重要,因为输送系统通常必须能够将沉重的负载从静止状态转移:在1:200的速度控制范围内,Sinochron系列可以立即施加全部启动扭矩来移动静止的负载 - 几乎从0到100。

强劲且紧凑

SINOCHRON®系列是永磁同步电机,由于其特殊的设计,非常适合无传感器操作。Stephan Thoma解释说:“他们非常有动力。”这种驱动解决方案与感应电机的不同之处在于,它的短时过载能力大约是感应电机的两倍。Ralf Fickentscher解释说:“此外,即使是最小的IEC机座号63,也能达到额定扭矩4.5 Nm,几乎翻倍的过载能力。由于电机实现了这种高功率密度,我们可以使我们的解决方案更紧凑。”因此,用户通常可以选择更小的电机,从而减少安装空间和能源消耗。

与同类变频器相比,该电机还可以在400 V下操作运行,而不是仅24 V。这使得项目规划更容易,因为多个变频器可以从一个电源操作,并根据所谓的菊花链原理串联开关 - 只需要一个电源。此外,变频器通过总线系统联网进行通信,因此可以从一个中心点进行控制。

通过无传感器速度控制,电子测量控制系统计算转速和转角在给定的时间。有了这些信息,产生扭矩的电流可以精确地反馈给电机。Thoma说:“我们无需使用昂贵的编码器就可以实现非常好的控制特性。”而且由于驱动器不需要任何传感器,因此也很耐用。就像那只著名的兔子的故事。Fickentscher说:“通过这种方式,用户还可以显著降低维护成本和获得的高系统可用性,这两者都是总体拥有成本的重要好处。该驱动器的使用寿命可达50000小时。”

模块化设计的定制化解决方案

ABM 格莱芬伯格还可以通过驱动解决方案满足用户的定制化需求。到什么程度? Thoma说:“这取决于具体要求,通过我们的智能模块化设计,我们可以为每个应用找到正确的解决方案,各种齿轮箱设计,如同轴、直角轴和平行轴齿轮箱,并由ABM开发、制造和调节各种电机的最佳性能值。由于其模块化设计,变频器也可以满足系统制造商的特殊要求与标准组件。这对质量有积极的影响,因为只有经过验证的模块才会被使用。”

通过这种模块化设计,系统供应商也减少了可能的不同产品的数量 - “ 通过它,我们控制了复杂性,” Thomas说。系统制造商还可以选择不同的机械接口,方便调试。驱动变量也可以减少,因为相同的电机系列通常可以用于各种应用。如果高负载需要在较低速度下获得更高的扭矩,电机可以简单地与齿轮箱结合,各种机械和电气接口可简化安装,许多连接实现为即插即用连接,这增加了系统的灵活性。

"但是,如果客户提出要求,我们也可以设计一个全新的解决方案, "Fickentscher解释道。通过定制化解决方案,用户可以获得最大的附加值和永久性、并显著的降低成本,因为驱动器完全适合其要求。

SINOCHRON® 电机应用在集装箱运输技术

无磨损直接驱动,无齿轮传动,无刹车,节能,高实用性:所有这些都使ABM解决方案均适用。除其他外,运输不同重量的集装箱的滚筒输送,通常超过几公里。“我们的电机效率高,功率密度高。此外,由于其紧凑的设计,它们是紧凑空间的理想选择。在SINOCHRON® 的驱动下,输送系统中的滚筒可以运送重达180 kg的货物,并使它们从静止状态加速。Thoma解释说:“启动负载需要高扭矩,在部分负载操作范围内,驱动程序90%的时间都在工作。”典型的旅行速度是0.3到1.5 m/s。

因为无齿轮传动,电机不需要油或润滑油,它们也可以用于食品工业。SINOCHRON® 驱动的另一个优势是它适用于冷冻存储设备:该系列产品可以在-30°C至+60°C的温度范围内使用。Thoma报告说:“相比之下,现有的滚筒电机只适合在0°C以下。

使用ABM驱动解决方案的用户之一是来自德国上普法尔茨州帕克斯坦的Witron 物流信息有限公司,单一来源的总承包商计划、实现和操作自动化物流和物料流系统,公司承担物流规划、信息与控制技术、机械设计与制造和运营责任,添加到其中的是项目的所有服务和维护任务。ABM SINOCHRON® 电机已被集成到Witron全球的物流系统中,目前正在与一家拥有数公里输送线的德国货物连锁店合作。Witron控制技术开发负责人Josef Uschold满意地说:“通过这些解决方案,我们可以减少安装空间和能源消耗,我对与ABM的合作印象尤其深刻,我们从一开始就是很好的伙伴关系,我们总是收到高质量和可靠的驱动组件。”

也适用于非常高的负载

但如果变频器必须驱动更高的负载 - 就像托盘输送的工况? Fickentscher解释说:“然后我们将一个现有的齿轮箱连接到电机上。”用户可以处理高达1200 kg的负载,并仍然受益于SINOCHRON® 电机的优点,如,紧凑的设计,在较大调速范围内的最大扭矩,或大量安装和集成选项。

“我们的紧凑型平行轴齿轮箱FGA可以安装使用于输送系统,例如,平行于电机轴。这使得U型设计和电机侧的输出轴成为可能,并使得这个解决方案更加紧凑” Thoma说。如果需要,也可以选择同轴齿轮箱。例如,直角轴齿轮箱可以横向安装,以节省空间。Fickentscher说:“我们总是与客户密切合作,实现他们的要求。”“为了使更高的外部径向力作用到齿轮箱上,我们将输出轴向前设计到法兰上,这是一个很大的优点,例如,对于预张紧的皮带输送或外部齿轮,因为施力点和轴承之间的距离大大减少,ABM齿轮箱也可以扩展,以产生额外的系统优势。通过灵活的安装和应用中进一步任务的额外假设,整个系统的优点出现了:例如,只需一个高效电机就可以实现多个动作,这节省了资金,加快了调试速度。

满足需求

Thoma说: “我们总是用我们最好的解决方案满足用户的需求。由于改进的模块化解决方案,客户从快速可用性中获益。工程合作伙伴和供应商为制造商提供高效的驱动解决方案 - 在自动化导引车辆、自动化物流系统 (包括传送带、起重设备和叉车) 或冷藏设备中。ABM 格莱芬伯格从单一的来源提供一切,全系列供应商在应用方面有超过十年的经验。Fickentscher强调说,全球有50多万套这样的驱动解决方案得到了成功应用。

例如,当增加一个直角轴齿轮箱时,可以以高效率和高功率密度输送非常高的负载。

增加输出轴中心距使驱动极其坚固耐用。

无传感器驱动的高能效,特别是在部分负载区域,显著降低了成本,确保了快速的投资回报。

适用于狭窄的空间: 平行轴齿轮箱+分散式变频器+永磁同步电机 (SINOCHRON® 电机)紧密配合到带式输送机。

在工业物流系统中,直角轴减速电机可以可靠、高效地驱动运输系统。

相同的web地址 - 新体验

>自2021年7月13日起,ABM格莱芬伯格将推出一个新网站,旨在为访问者提供有吸引力的现代化设计,并结合友好体验度,以确保快速访问信息。

清晰的菜单栏和优化的内容,让每个人 - 无论是现有客户,潜在客户,还是求职者,只需少量的点击就能得到想要的信息。

虽然为客户提供了特定的门户,但业内客户可以非常舒适地展示其应用和行业的产品推荐。职业门户页面向中学生、大学生和专业经验人士介绍所有选择,以及 ABM Plus 和福利,会将 ABM区分为有吸引力的公司。

随着新网站的建立,相关人士能够真正了解我们公司,ABM格莱芬伯格:用户可以看到真实的ABM员工。新的企业视频不仅引导您参观工厂,还会将 ABM 定位为有吸引力的公司。

除了对内容进行全面修订外,还更新了相应的技术,并更新了新的内容管理系统,包括响应式页面设计。用户可得到受益,从所有移动设备上的缩短下载时间和最佳的演示。

很快,社交媒体将成为网络的补充,我们期待通过LinkedIn让所有感兴趣的各方了解新闻、产品开发和有用的实用技巧。